SBR technology offers an advanced wastewater treatment method with the ability to operate in independent cycles. This intelligent design not only optimizes treatment efficiency but also ensures that the treated water quality meets the most stringent standards, making SBR tanks a superior choice for modern wastewater treatment systems.

Introduction to SBR tanks in wastewater treatment

What is an SBR tank in wastewater treatment?

The SBR (Sequencing Batch Reactor) tank is a modern wastewater treatment system that operates in independent cycles. Wastewater is introduced into the tank, where aeration, sedimentation, and water discharge processes occur sequentially within the same space, optimizing the treatment process.

This technology is suitable for treating both domestic and industrial wastewater, especially in areas with unstable wastewater flow. SBR tanks effectively remove organic compounds and nitrogen from wastewater, resulting in treated water that meets safety standards.

Structure of the SBR tank

The structure of the SBR tank consists of two main parts: the Selector tank and the C-Tech tank, which are designed to be closely linked to ensure effective wastewater treatment. The Selector tank performs preliminary treatment, helping to remove initial impurities in the wastewater before it is transferred to the C-Tech tank. Here, the main treatment processes such as aeration and sedimentation take place, ensuring the wastewater is thoroughly treated before being discharged into the environment.

These two tanks work harmoniously, complementing each other, and the absence of any part can hinder the system's efficiency. The SBR tank structure typically has a rectangular shape, with solid concrete walls. The system also includes components like aerators, sludge pipes, and a water discharge system, all scientifically arranged to optimize the wastewater treatment process.

Advantages of SBR technology

- Reduced costs and construction time: There is no need to build additional settling tanks (I, II), aerotanks, and equalization tanks, optimizing costs and shortening construction time.

- Thorough removal of organic matter: SBR tanks eliminate most organic compounds in wastewater, ensuring the treated water is safe for the surrounding aquatic ecosystem.

- Space-saving: All complex treatment processes occur in a single tank, saving space and minimizing construction area.

- Easy incident control: Since the processes occur within the same tank, any incidents that arise can be quickly and flexibly identified and addressed.

- Suitable for various system capacities: SBR technology operates efficiently across systems of varying capacities, from small to large, ensuring stable operation.

- Energy savings: The SBR wastewater treatment process consumes less energy compared to traditional methods, helping reduce operational costs.

- Ability to handle high pollution concentrations: SBR tanks effectively treat wastewater with high pollution concentrations, particularly complex organic substances.

- Flexible operation: The tank can operate flexibly and can be easily adjusted according to specific system treatment requirements and environmental conditions.

- Applicable to all systems: SBR technology can be deployed in various types of systems, ensuring diversity and effective wastewater treatment.

Disadvantages of SBR wastewater treatment technology

- Complex operational requirements: SBR tanks require sophisticated operational processes, demanding advanced technology to ensure the system operates efficiently.

- High technical demands: Operators must have a high level of expertise to ensure smooth and accurate operation.

- Susceptibility to sludge clogging: The system risks clogging due to sludge accumulation, necessitating effective control measures.

- Need for additional equalization systems: In cases of shock loading or overload, an equalization tank is necessary to support stable operation.

- Requirement for modern monitoring systems: The system must be equipped with advanced monitoring devices to track and control key technical indicators accurately.

- Maintenance difficulties: Maintaining and servicing the SBR system is complex and requires high expertise, potentially increasing maintenance costs.

- Design requirements for the tank: For structures with low load-bearing capacity, careful consideration is needed in design and construction of additional supporting equalization tanks to prevent overload on the system.

Topic on wastewater treatment using SBR technology

The topic of SBR tanks in wastewater treatment related to the process of nitrate removal is divided into two main phases. The first phase is the nitrification process, during which nitrogen compounds are oxidized. The next phase is denitrification, where nitrogen compounds are reduced to a state that no longer carries a positive valence.

The ASBR (Advanced Sequencing Batch Reactor) is an advanced biological tank designed to optimize the treatment process and overcome the limitations of traditional biological tanks. This tank effectively treats pollutants such as nitrogen (N) and phosphorus (P) in wastewater. Compared to SBR tanks, which are suitable for smaller capacity systems, ASBR tanks are preferred in larger capacity systems due to their ability to produce minimal excess sludge. However, since the ASBR system is fully automated, operators must have a high level of technical expertise.

The MBR (Membrane Bioreactor) wastewater treatment technology combines biological and physical methods. MBR filters can be used in aerobic or anaerobic biological tanks, ensuring high effluent water quality by removing bacteria and pathogenic microorganisms such as Coliform and E. Coli. The advantage of this technology is that the filters are coated with a hydroxyl group polymer layer, extending their lifespan and enhancing the durability and stability of the system.

Viet An is a leading unit in providing environmental monitoring solutions in Vietnam. We specialize in offering automatic wastewater monitoring solutions, with over 1,000 monitoring stations deployed nationwide.

Operating principles of SBR wastewater treatment tanks

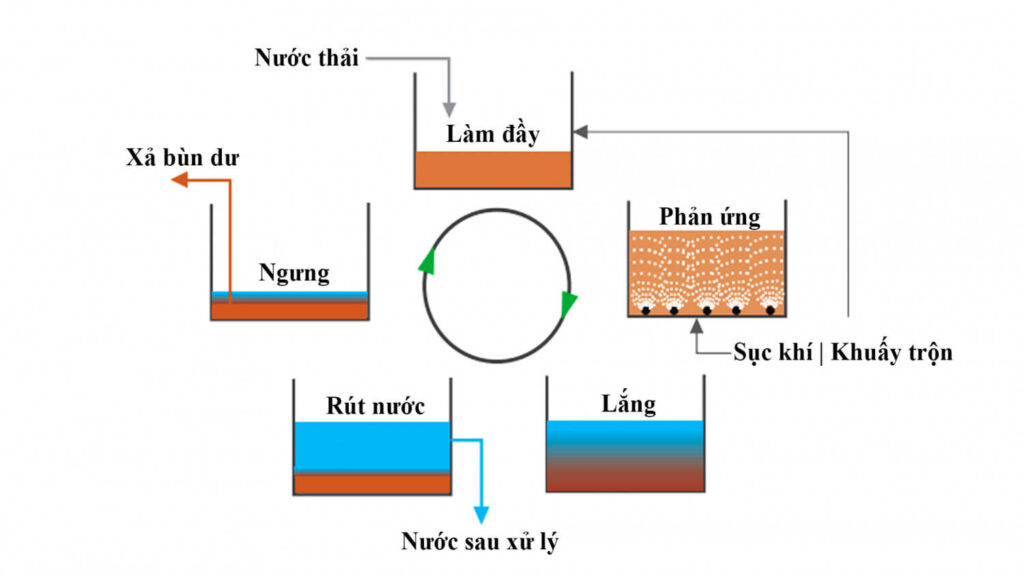

SBR tanks operate in a closed-loop cycle, divided into five main phases: filling phase, aeration phase, sedimentation phase, water discharge phase, and resting phase. The resting phase is the waiting period to prepare for a new treatment batch and depends on specific operating times. Therefore, the wastewater treatment process mainly occurs during the first four phases.

Filling phase

During the filling phase, wastewater is introduced into the treatment tank over a period of 1 to 3 hours. During this time, the tank performs the necessary treatment steps to prepare for the next batch. These steps may include: filling - static, filling - mixing, and filling - aeration, depending on the BOD content of the incoming wastewater.

When wastewater is introduced into the tank, it not only provides pollutants but also feeds microorganisms and activated sludge in the tank. This facilitates biochemical reactions, helping microorganisms work more efficiently in treating organic matter.

The process of pumping wastewater into the tank is carried out continuously and flexibly, with filling phases adjusted based on treatment goals and the characteristics of the wastewater.

Aeration phase

In this phase, the main goal is to supply oxygen to the wastewater and evenly mix the contents in the tank. This optimizes the biochemical reaction process between activated sludge and the pollutants in the wastewater.

Aeration not only provides oxygen but also increases contact between the sludge and pollutants, supporting the denitrification process. Nitrogen in the wastewater is converted from ammonium (N – NH3) to nitrite (N – NO2) and then to nitrate (N – NO3).

The aeration process is conducted at high flow rates to ensure sufficient oxygen supply and effective mixing. The aeration duration typically lasts about 2 hours, depending on the wastewater quality, and plays a crucial role in promoting the nitrification reaction, thereby enhancing the efficiency of wastewater treatment.

Sedimentation phase

In this phase, the organic substances in the wastewater settle at the bottom of the tank in a static environment. This process allows the sludge to concentrate and settle completely. The sedimentation time usually lasts about 2 hours to ensure optimal sedimentation efficiency.

Water discharge phase

After the sludge has completely settled at the bottom of the tank, the clear water above will be withdrawn from the tank without carrying any activated sludge. When the wastewater has been treated and clearly layered, the floating water will be discharged to move to the next treatment step. The amount of water removed in this phase is entirely separate from the sludge, ensuring that clean water is sent to subsequent treatment steps without mixing with sludge.

Key notes on SBR wastewater treatment

In the nitrification process

- Substrate concentration: Ensure a high substrate concentration to provide sufficient nitrogen for the microorganisms. A rich substrate helps optimize treatment efficiency since microorganisms need nitrogen for growth.

- Temperature: Higher temperatures will improve the speed and efficiency of the treatment process. Maintaining a stable temperature is essential for achieving optimal performance.

- Oxygen supply: To oxidize 1 mol of NH4+, approximately 1 mol of O2 is required (4.57 g O2/g nitrogen). Provide sufficient oxygen to support the nitrification process.

- pH level: The ideal pH for the nitrification process is between 7 and 9. A pH below 6.2 or above 10 can reduce efficiency due to adverse effects on microorganisms.

- Sludge retention time and toxicity: The sludge retention time and the presence of toxins in the wastewater can affect the efficiency of the nitrification process.

In operation

- Impact of Oxygen: Oxygen affects the concentration of activated sludge and biofilm. Providing sufficient oxygen is essential to maintain the effective functioning of microorganisms and the biofilm.

- pH Level: A pH level between 7 and 9 is optimal for the denitrification process. Maintaining the pH within this range ensures that the denitrification process occurs effectively.

- Temperature: Temperature affects the rate of denitrification. Temperatures between 10 and 25°C can double microbial activity, while temperatures from 50 to 60°C can reduce the rate to 50% compared to 35°C.

- Organic Compounds: Soluble and easily degradable organic compounds also impact the denitrification process. Ensuring the presence and quality of these compounds is essential to promote the treatment process.

- Operational Factors: Factors related to the operation of the SBR tank, such as phase adjustment and sludge management, can affect the efficiency of the denitrification process. Optimizing operational procedures is necessary to avoid reducing treatment performance.

Conclusion

SBR technology provides an effective solution for wastewater treatment, capable of meeting stringent quality standards. With support from Việt An, a leading unit in environmental monitoring, especially in automatic wastewater monitoring with over 1,000 stations nationwide, you can be assured of maintaining effective treatment and protecting the environment.