Boiler water quality control is critical for ensuring the performance, safety, and longevity of industrial boiler systems. Discover the Swiss SWAS (Steam and Water Analysis System) solution, designed to prevent scaling, corrosion and optimize operational efficiency.

When water is boiled to produce steam, minerals and impurities from the feedwater accumulate and form boiler scale deposits. If not properly treated, these deposits can lead to serious operational issues.

Boiler Scale and Its Adverse Effects

The heating process that turns feedwater into steam gradually leads to the formation of boiler scale deposits such as:

- Calcium Carbonate (CaCO₃)

- Calcium Sulfate (CaSO₄)

- Calcium Silicate (CaSiO₃)

- Silicates and other impurities

These scale layers inside the boiler reduce heat transfer efficiency, increase operational costs, and pose serious risks such as blockages and even boiler explosions.

Why Is Boiler Water Quality Control Essential?

If not properly treated, precipitated scale deposits can cause blockages, reduced heat transfer efficiency, and lead to the following critical issues:

- Pipe Blockage: Scale buildup reduces water flow, which may result in boiler overheating, equipment damage, or even boiler explosion..

- Metal CorrosionDissolved gases such as CO2, O2 in the water, when combined with high temperatures, promote metal oxidationdecreasing structural integrity and causing leakage in piping systems.

- Reduced: Scale layers impede heat transfer, increasing operational costs and shortening the boiler's service life.

Due to the issues affecting boilers as mentioned above, boiler water quality control is based on three main principles:

- Scale Prevention: Minimizing the accumulation of scale and deposits on tube surfaces.

- Corrosion Control: Protecting the metal tube walls from damage.

- Dissolved Oxygen Removal: Preventing oxidation to enhance system durability.

Boiler Water/Steam Analysis Solution

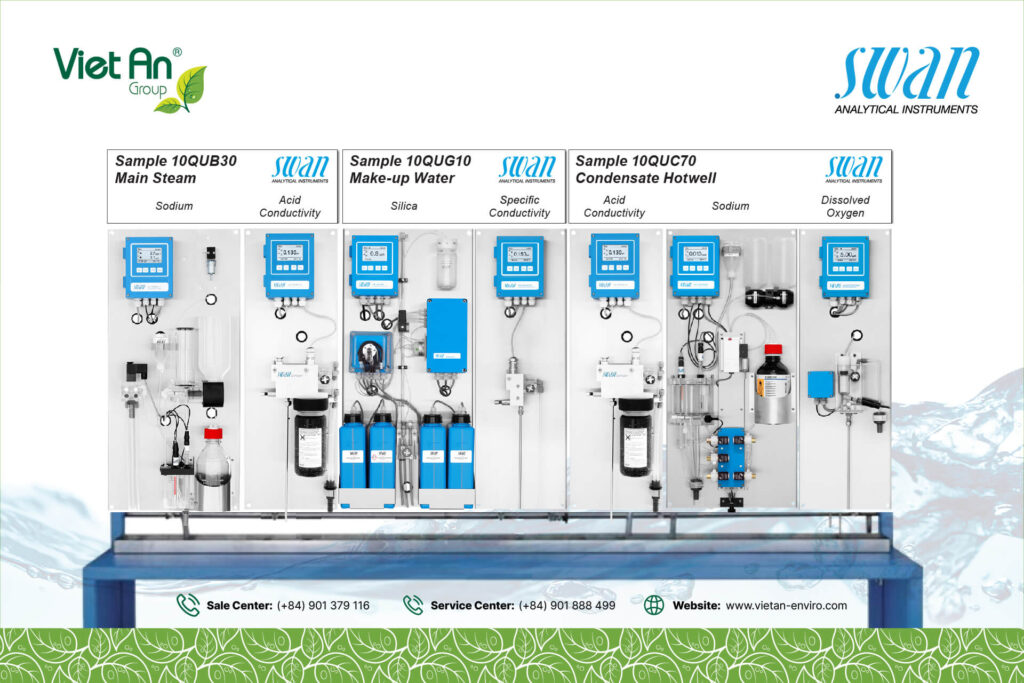

The SWAN Water and Steam Analysis System (SWAS) from SWAN is an advanced solution for monitoring and measuring critical parameters, including:

- pH.

- Conductivity

- Dissolved oxygen concentration

- Sodium (Na+), Silica (SiO2), Phosphate (PO4), Ammonium (NH4+).

Key Features of SWAN's SWAS Solution

- Enhanced Boiler Efficiency and Longevity

- Reduced Downtime and Extended System Lifespan

- Flexibly customizable to meet the specific needs of each customer

- High-quality measurement instruments enhance system safety and operational efficiency.

- Modular design allows for easy customization and integration of auxiliary equipment.

Contact Viet An Enviro for professional consultation on SWAS solutions.

Việt An Enviro is the official distributor of SWAN's Boiler Water and Steam Analysis System SWAN in Vietnam. With over 1,000 monitoring stations nationwide, 14 years of experience, and a trusted partnership with more than 1,500 organizations and enterprises, we are committed to delivering:

- High-Quality Equipment 100% officially imported from the EU/G7 with full certificates of origin (CO) and quality (CQ).

- Comprehensive Services : Manufacturer warranty, user training, and operational support.

- Our technical service team accompanies customers throughout the product lifecycle to ensure reliable and accurate system performance.

- Our team at Viet An is here to provide personalized advice and technical support for your environmental monitoring and industrial measurement needs. We're committed to helping you optimize your investment.

Việt An – Thị phần số 1 Việt Nam về Giải Pháp Quan Trắc Môi Trường và Đo Lường Công Nghiệp

🔘 Head Office (Ho Chi Minh City)

No.4E, Street 6, An Phu Ward, Thu Duc City, Ho Chi Minh City

(Sales) +84 902 970 009 | (Service) +84 901 888 499

🔘 Northern Viet An

Lô 33, khu BT4-1, khu nhà ở Trung Văn, phường Trung Văn, quận Nam Từ Liêm, Hà Nội

(Sales) +84 901 851 116 | (Service) +84 901 888 499

🔘 Central Viet An

No.5A Mai Xuan Thuong Str., Hoa Khe Ward., Thanh Khe Dist., Da Nang City

(Sales) +84 898 119 116 | (Service) +84 901 888 499

🔘 Việt An VP-Hà Tĩnh

03 Mai Thúc Loan, phường Kỳ Liên, Thị xã Kỳ Anh, Hà Tĩnh

(Sales & Service) +84 938 442 414

FAQ – Boiler Water Quality Control

- What is SWAS?

SWAS (Steam and Water Analysis System) monitors key parameters such as pH, conductivity, and dissolved oxygen to ensure the quality and safety of boiler water. - Why control dissolved oxygen?

Controlling dissolved oxygen prevents metal oxidation, protects boiler components from corrosion, and extends system lifespan. - How to prevent boiler scale formation?

Use a SWAS system for real-time monitoring and timely water treatment, in combination with chemical and mechanical methods to remove scale and deposits.