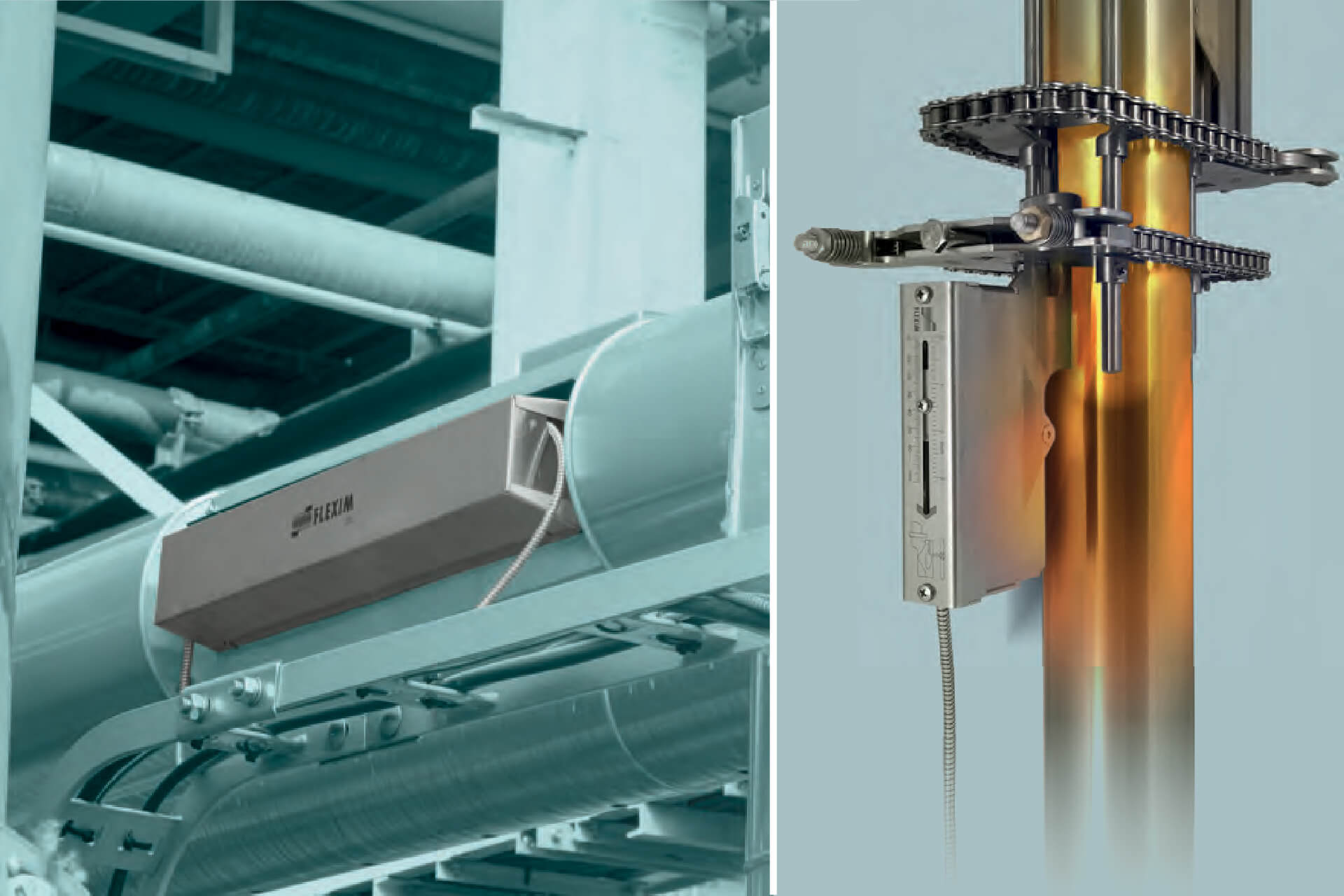

Flexim is brand Number 1 in the world in providing external pipe clamp ultrasonic flow measuring equipment.

Advantages of Flexim's external clamp ultrasonic flow measurement technology

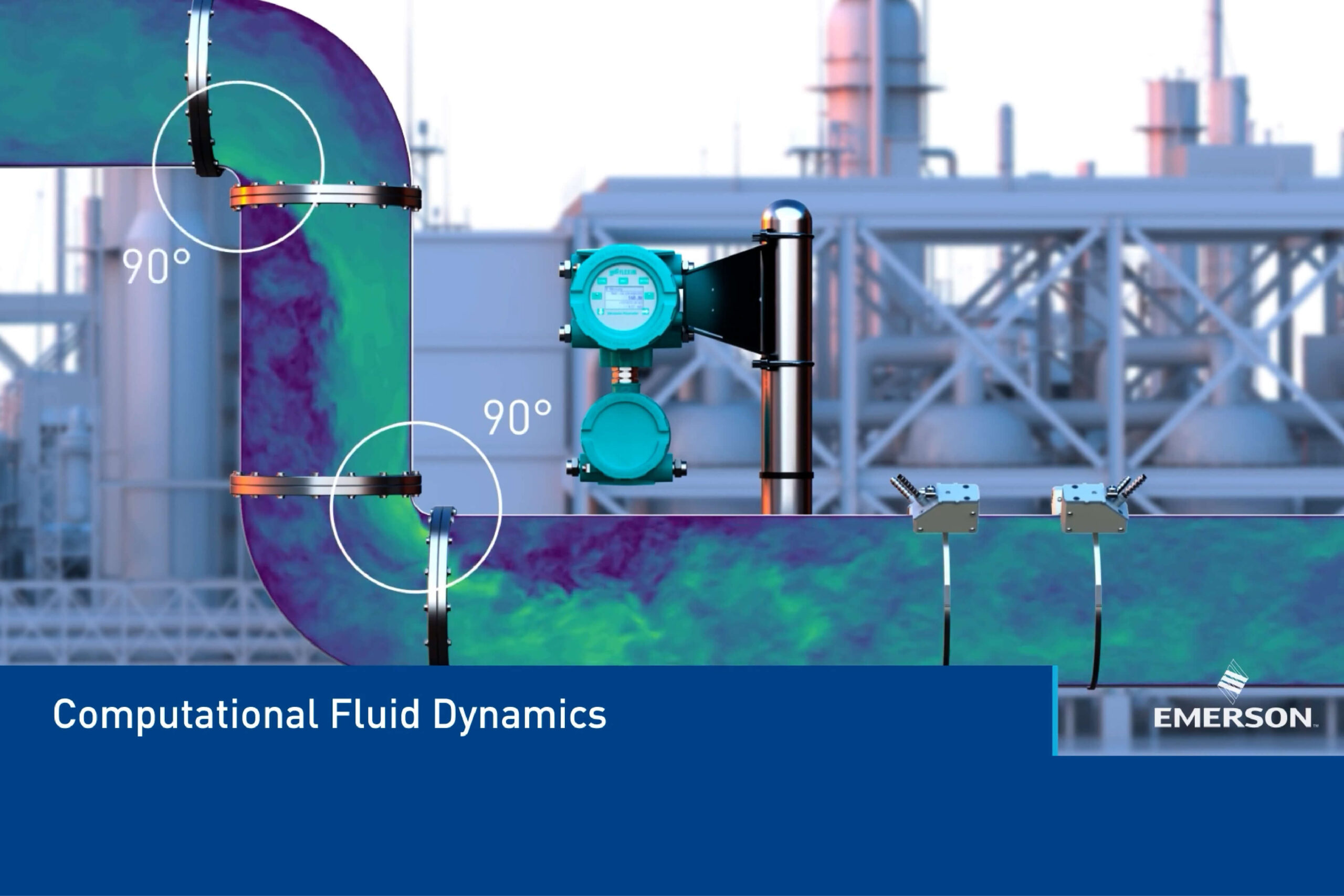

The primary distinction of Flexim’s ultrasonic flow measurement devices compared to other brands on the market lies in their ability to diagnose the quality of transmitted and received signals between transducers, enabling optimal placement selection even when standard installation conditions (e.g., 10D upstream and 5D downstream of the device) are not met, as well as the capability to input the speed of sound (C) parameter for accurate measurements in cases involving old or aging pipelines.

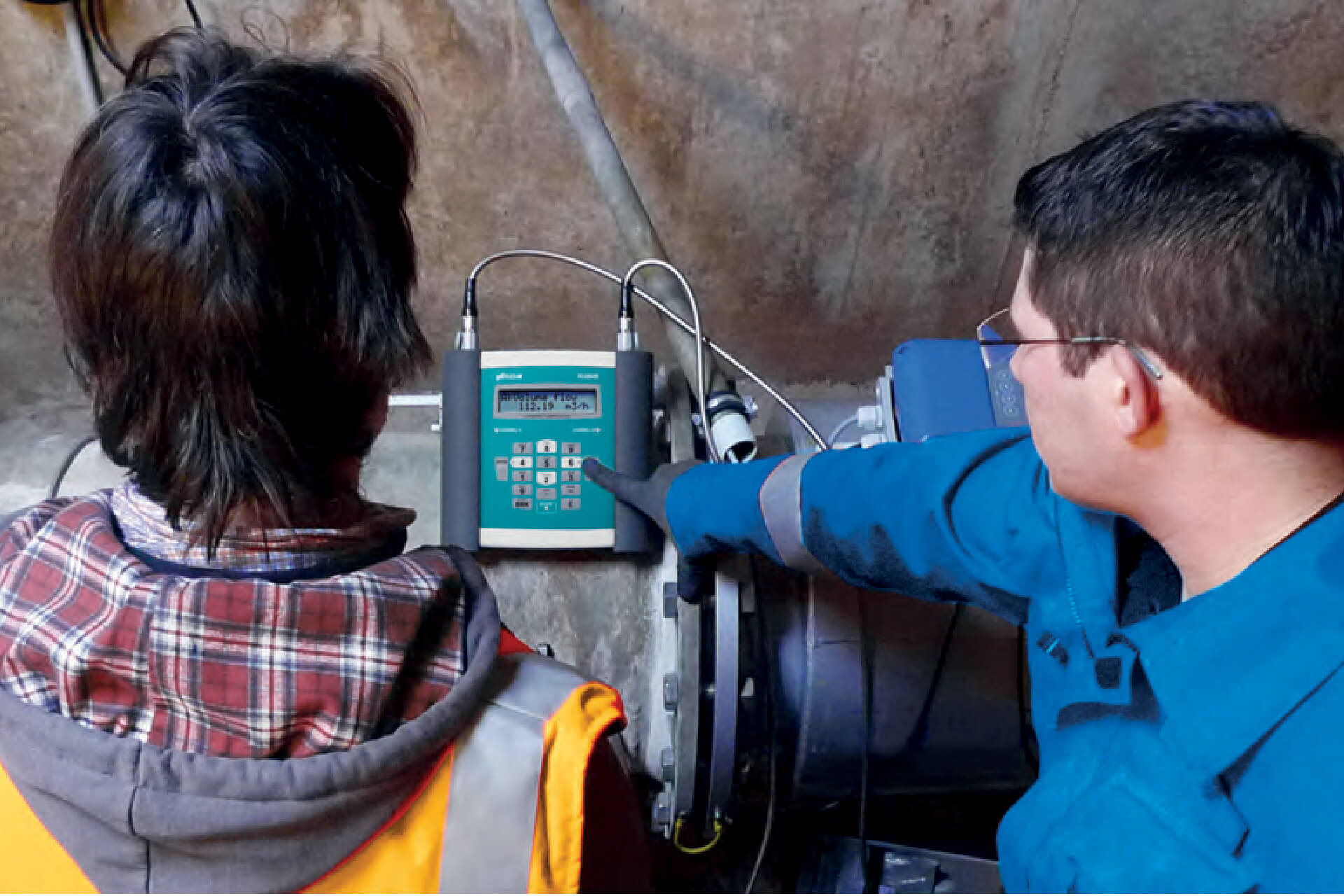

Flexim’s clamp-on ultrasonic flow measurement technology is available in two configurations: portable and fixed installation. These devices enable rapid flow measurement on pipelines or quick verification of the accuracy and stability of installed flow meters, saving time, labor, and costs. They are easy to install and operate.

- Wide pipe diameter range. High accuracy (1% with two pairs of transducers and 2% with one pair of transducers) and stable performance.

- Capable of measuring on various pipe materials, with integrated pipe wall thickness measurement and data storage capacity for up to 100,000 values. Notably, the device enables water flow measurement on old or aging pipelines without the need for pipe cutting.

- Wide measurement range for pipe diameters from DN6 to DN6500.

- Rapid installation, enabling measurements within 5–10 minutes, facilitated by pre-assembled mounting accessories with included magnetic fixtures.

Viet An Enviro would like to introduce to customers the equipment for checking network flow and pipeline flow for water plants from Flexim - Germany, of which our company is the sole distributor in the market. Vietnam.

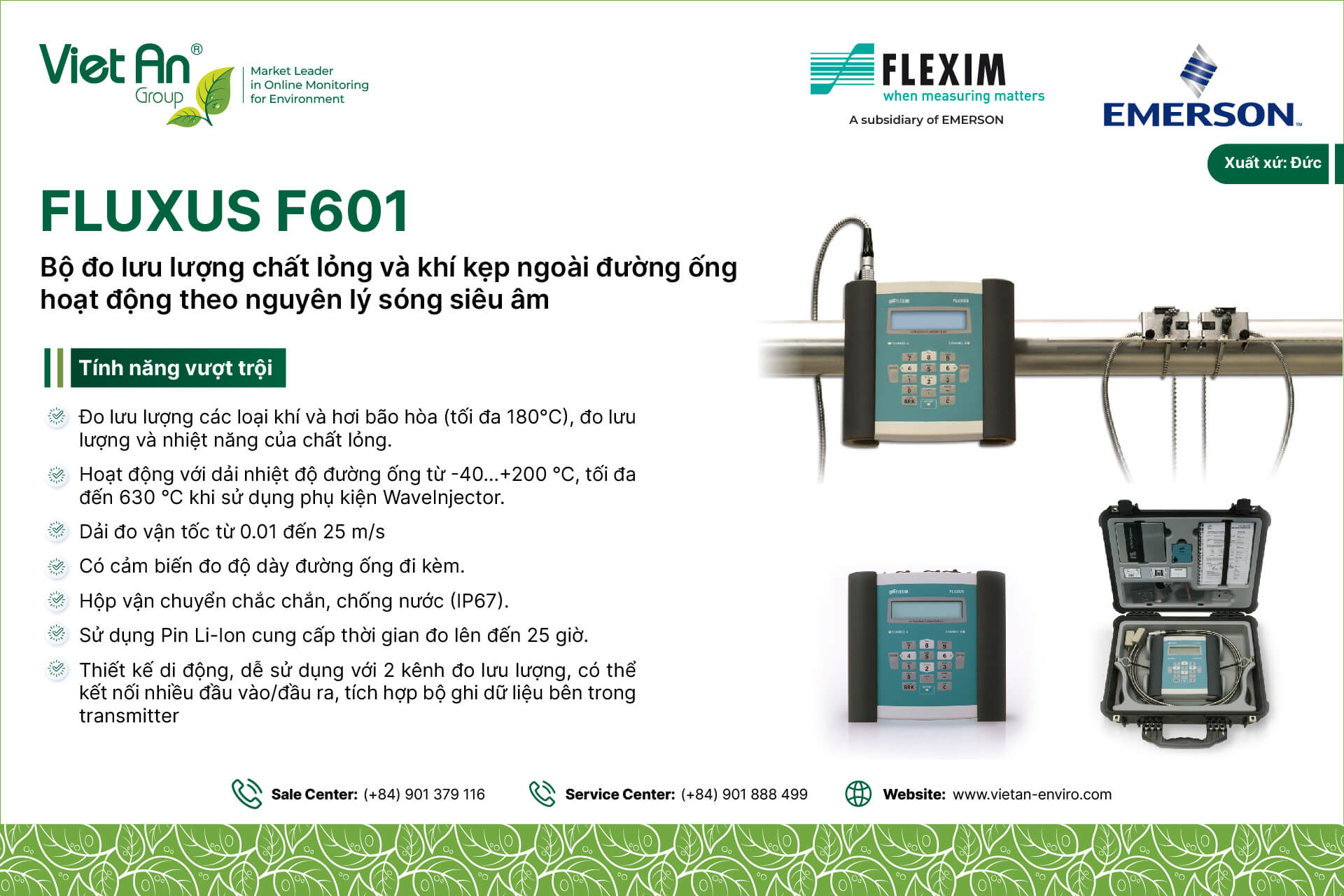

Fluxus F601/G601

The Fluxus F601/G601 flow meter from Flexim measures the flow rate inside pipelines using clamp-on ultrasonic technology. The Fluxus F601/G601 is a portable device that enables non-intrusive flow measurement without the need for pipe cutting, delivering rapid results through ultrasonic wave technology. Designed for pipe diameters ranging from 6mm to 1600mm, this handheld clamp-on device ensures quick and accurate flow measurement.

Key Features of the F601/G601

- Bidirectional flow measurement with high flexibility using non-invasive clamp-on ultrasonic technology.

- Exceptional accuracy for both low and high flow velocities, with excellent stability at high temperatures and near-zero flow conditions.

- For liquid media, the device features a dual-channel display, multiple input/output interfaces, and a serial interface for signal logging.

- IP65-rated protection against water, oil, and dust ingress.

- Li-Ion battery supports up to 14 hours of continuous measurement operation.

- Automatic calibration data loading, quick sensor recognition, and easy setup in under 5 minutes, delivering long-term stable and accurate results.

- User-friendly interface and ergonomic design for enhanced ease of use.

- Wide sensor compatibility, capable of handling pipe inner diameters from 6 mm to 6500 mm, and fluid temperatures from -40°C to +400°C.

- Optional wall thickness measurement probe available.

- Rugged and waterproof design (IP67) for easy transport, with neatly organized accessories for convenient deployment.

- HybridTrek mode automatically switches between Transit Time and NoiseTrek modes to ensure accurate measurement even in fluids with high particulate concentration.

- Designed for quick installation and maintenance, with reliable flow data transmission under challenging and harsh field conditions.

Applications of FLUXUS F601/G601 F601/G601

- Chemical industry

- Water supply and wastewater treatment industry

- Oil and gas industry

- Cooling and HVAC (Heating, Ventilation, and Air Conditioning) systems

- Aviation industry

Fluxus G608

The Fluxus G608 by Flexim is a clamp-on ultrasonic gas flow meter designed for use in hazardous areas. It is a portable, non-invasive device that measures gas flow without the need to cut or modify existing pipelines, and is suitable for pipe diameters ranging from 6 mm to 1600 mm.

Features

- Measures bidirectional flow with high flexibility using a clamp-on pipe method.

- Extremely high accuracy for both fast and slow flow rates, stable at high temperatures and zero point.

- Constructed with a durable carbon housing.

- Certified to FM Class I Div. 2 standards.

- Li-Ion battery supports up to 14 hours of continuous measurement operation.

- Automatic calibration data loading, quick sensor recognition, and easy setup in under 5 minutes, delivering long-term stable and accurate results.

- The sensor unit operates over a wide range, with pipe inner diameters from 10 mm to 6500 mm and fluid temperatures from -40°C to +400°C.

- The sensor enclosure meets FM Class I Div. 2 standards, capable of withstanding harsh environments and humidity.

- Robust, waterproof (IP67) design, easily transportable with compact, convenient accessories.

- Designed for quick installation and maintenance, with reliable flow data transmission under challenging and harsh field conditions.

Application

- Upstream (onshore and offshore)

- Oil pipeline and refining

- Industrial chemicals

- Energy sector (e.g., HVAC, geothermal, power plants)

FLUXUS F721

The FLUXUS F721 employs a non-invasive measurement method, eliminating the need for pipe cutting or system interference, resulting in cost-effective installation and maintenance.

Key Features of FLUXUS F721

- High measurement accuracy across extremely low to very high flow rates, independent of flow direction (bidirectional).

- Advanced self-diagnosis and event-based data logging for monitoring and controlling critical processes.

- Quick installation without requiring pipe modifications or process interruptions.

- Individually calibrated display unit and transducers ensure measurement accuracy and optimized performance, enhancing measurement consistency.

- Transducer options available for various pipe diameters and fluid temperature ranges from -200°C to +600°C.

- Optional display unit and transducers for explosion-proof areas.

- Applications across multiple industries, including petrochemicals, oil and gas, pharmaceuticals, semiconductors, manufacturing, energy management, water and wastewater, and mining.

Applications of Flexim FLUXUS F721

The FLUXUS F721 is an ideal liquid flow measurement solution for various industries in Vietnam, from manufacturing and energy to wastewater treatment. Below are the primary applications of the device:

Oil and Gas Industry

- Hydrocarbon Flow Measurement: The FLUXUS F721 accurately measures the flow of hydrocarbon liquids in oil and gas processing plants, ensuring compliance with industry standards such as ASTM1250, GPA TP25, D4311, and ISO 91.

Water and Wastewater Industry

- Drinking Water and Wastewater Flow Measurement: The FLUXUS F721 WD, a variant of the F721 series, is optimized for flow measurement in drinking water supply and wastewater treatment systems. It can measure flow rates as low as 0.01 m/s, making it ideal for leak detection and nighttime flow monitoring.

Manufacturing and Processing Industry

- Process Monitoring: The FLUXUS F721 is used to monitor liquid flow in chemical, food and beverage, and pharmaceutical industries, ensuring quality control and process optimization.

- Low Flow Measurement: The FLUXUS F721XLF variant is designed for ultra-low flow rates (down to 6 L/h), suitable for high-precision applications such as specialty chemical production.

Energy Industry

- Flow Management in Power Plants: The device supports flow measurement of cooling liquids, lubricants, or other fluids in thermal and hydroelectric power plants.

Other Applications

- Environmental Monitoring: Measures flow in industrial wastewater treatment systems or monitors flow in environmental protection projects.

FLUXUS F731WD

Ultrasonic Clamp-On Flow Meter for Prestressed Concrete Cylinder Pipe (PCCP)

Key Features of FLUXUS F731 WD

- Measures ultra-low flow rates down to 0.01 m/s, ideal for precise monitoring of minimal flow during nighttime operations.

- Quick installation without pipe interference (cutting or sawing) or water supply interruption.

- No requirement for straight pipe lengths before or after the device to ensure measurement accuracy.

- No need for zero-point calibration and no zero drift.

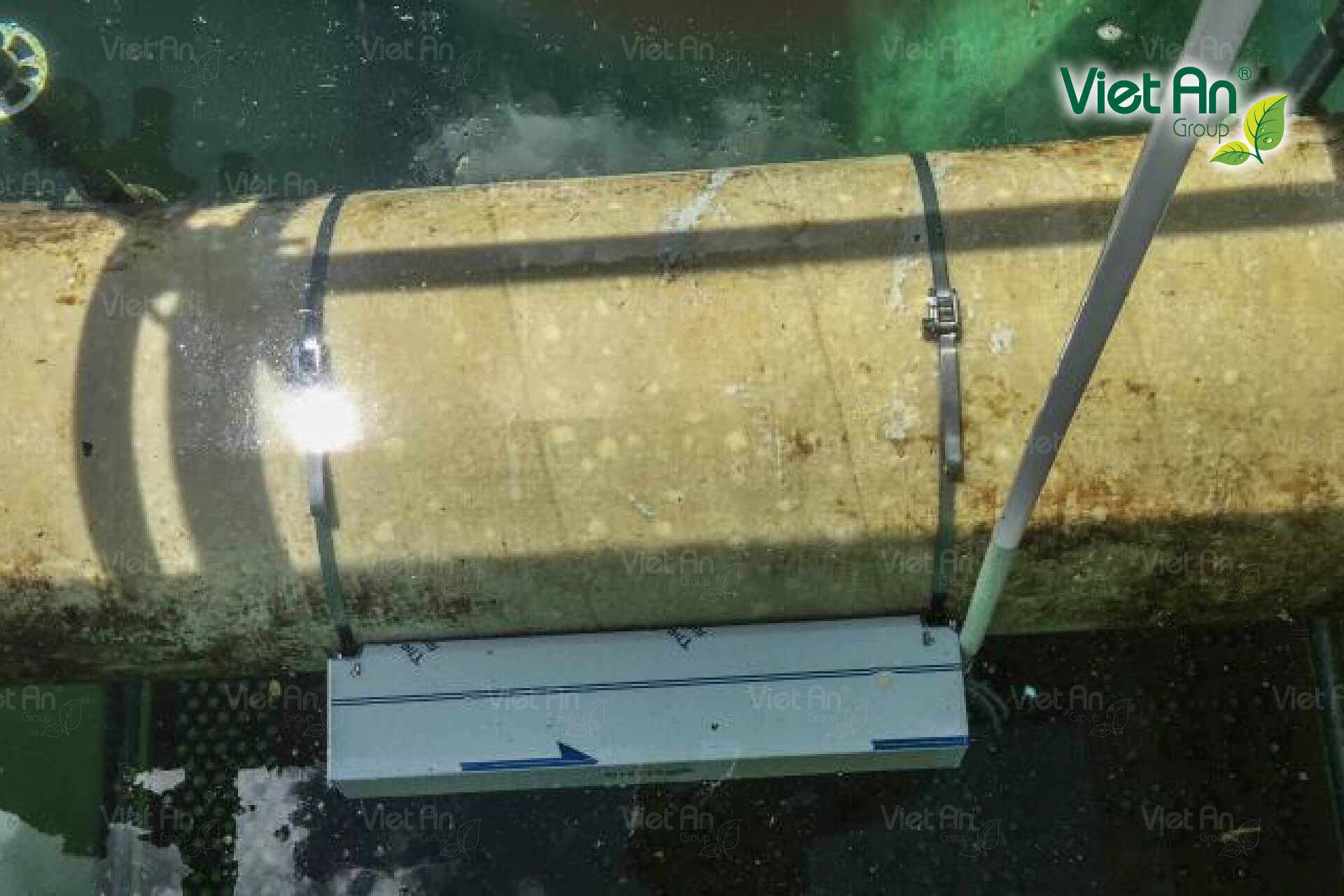

- Equipped with two IP68-rated waterproof sensors.

- Compatible with pipe diameters ranging from 50 mm to 6500 mm.

Applications of Flexim FLUXUS F731 WD

The Flexim FLUXUS F731 WD is specifically designed for water industry applications, including:

Clean Water Flow Measurement

- Water Distribution Network Management: The device supports flow monitoring in clean water distribution systems, optimizing supply operations and enabling early leak detection.

- Nighttime Flow Monitoring: With its ability to measure low flow rates down to 0.01 m/s, the FLUXUS F731 WD is ideal for monitoring water flow during low-demand nighttime periods, helping to identify system anomalies.

- Harsh Environment Installation: Equipped with IP68-rated protection, the device is suitable for measurement points in manholes, underground, or flood-prone areas.

Wastewater Treatment

- Wastewater Flow Monitoring: The device provides accurate flow measurement in wastewater treatment plants, ensuring compliance with environmental regulations.

- Complex System Applications: Its dual-channel measurement capability and compatibility with large pipe diameters make the FLUXUS F731 WD suitable for large-scale wastewater treatment systems.

Leak Detection and System Optimization

- Leak Detection: The high sensitivity of the device enables the detection of small leaks in water networks, minimizing resource wastage.

- Operational Optimization: Accurate measurement data supports water system managers in making informed decisions for maintenance and infrastructure upgrades.