What is a heat transfer oil furnace?

A heat transfer oil furnace is an industrial device that uses circulating oil to transfer heat, widely applied in industries such as paper, plastic, wood, and chemical production.

Controlling the flow rate of circulating oil plays a critical role in maintaining the efficiency and safety of the furnace. Flow measurement devices from Viet An Enviro enable accurate monitoring, ensuring stable operation.

In a textile fiber manufacturing plant, a specialized heat transfer oil is used to supply heat for the fiber drying process. To ensure efficiency and safety, flow measurement solution in the pipeline system is essential. The oil is heated to 280°C and transported through insulated pipelines to various production areas.

The oil, after losing heat, is circulated back and reheated to a temperature of 280°C. This process occurs continuously and in a closed loop. Measuring the flow rate of the liquid oil through the pipeline must be done accurately to calculate the amount of heat energy supplied to the production system.

Why is it necessary to measure the flow rate of circulating oil in a heat transfer oil furnace?

Measuring the flow rate of circulating oil provides several essential benefits:

-

Optimizing heat transfer efficiency: Ensures sufficient oil circulation for effective heat transfer.

-

Preventing incidents: Timely detection of overload or oil shortage conditions, reducing the risk of equipment failure.

-

Cost-Effective :: Minimizes energy waste and maintenance costs.

-

Meeting environmental standards: Supports adherence to emissions monitoring and environmental protection.

Traditional heat transfer oil flow measurement technology

Before the introduction of FLEXIM ultrasonic flow measurement technology, flow rates were typically determined using differential pressure or Vortex methods. However, these methods required production to be halted annually for system inspection and maintenance. Measurement points are often located in hazardous areas, necessitating special preparation and precautions for all maintenance activities.

Flow measurement solution for heat transfer oil furnaces from Viet An

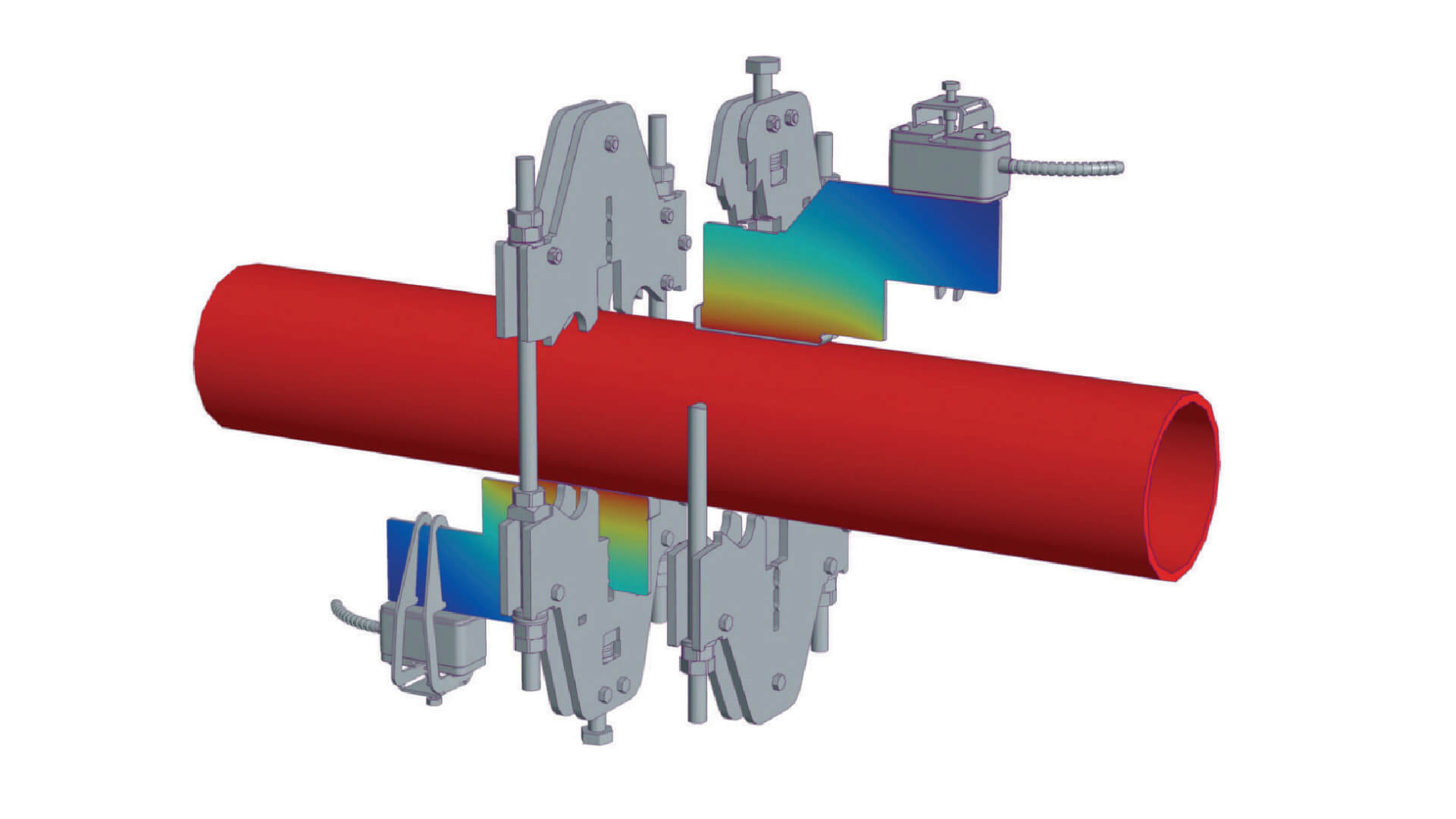

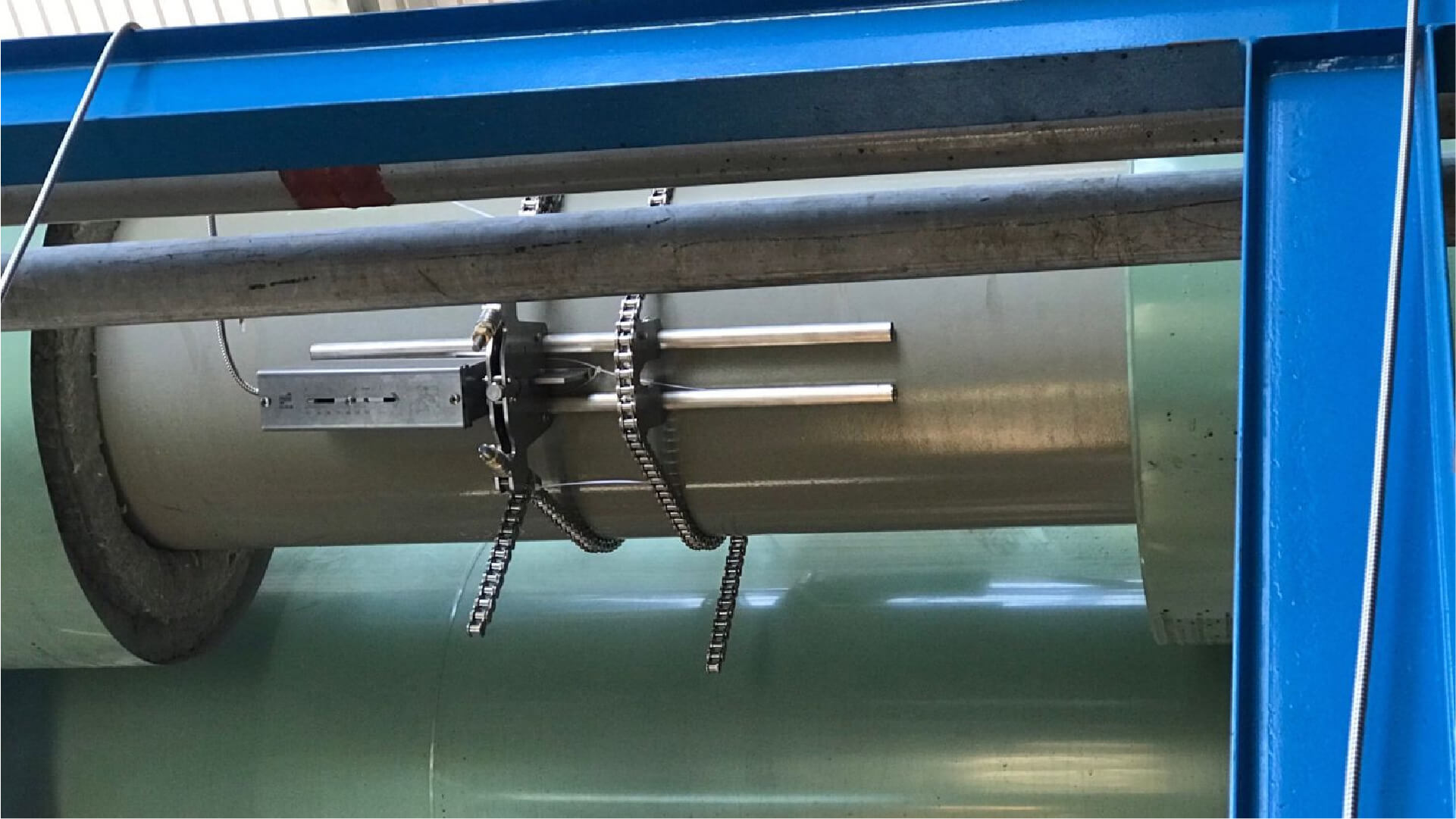

Application flow measurement solution using FLEXIM’s clamp-on pipeline probes and WaveInjector is a convenient and optimal approach to this measurement challenge. Since the probes do not come into contact with the medium, there is no physical or chemical corrosion.

The flow meter is installed without the need for welding or cutting the pipeline, thus eliminating any potential risks of dangerous leaks. FLEXIM’s ultrasonic oil flow monitoring technology is not only environmentally safe but also enhances overall plant efficiency and safety.

See equipment details or receive a quote: Here

Outstanding Benefits of Fluxus F721 + WaveInjector in Oil Flow Measurement

- Direct oil flow measurement on the pipeline: No need for pipe cutting, ensuring no disruption to the production process.

- Specialized solution : Suitable for installation on pipelines with temperatures up to 400°C or as low as -200°C.

- Explosion-proof design : Safe for use in flammable and explosive work environments.

- Non-abrasive operation: Minimizes maintenance needs and prevents value drift.

Contact Viet An Enviro

If you need equipment for measuring the flow rate of circulating oil in heat transfer oil furnaces or environmental monitoring:, contact Viet An Enviro immediately for detailed consultation:

🔘 Trụ sở chính (Việt An TP.HCM)

No.4E, Street 6, An Phu Ward, Thu Duc City, Ho Chi Minh City

(Sales) +84 902 970 009 | (Service) +84 901 888 499

🔘 Việt An Miền Bắc

Lô 33, khu BT4-1, khu nhà ở Trung Văn, phường Trung Văn, quận Nam Từ Liêm, Hà Nội

(Sales) +84 901 851 116 | (Service) +84 901 888 499

🔘 Việt An Miền Trung

No.5A Mai Xuan Thuong Str., Hoa Khe Ward., Thanh Khe Dist., Da Nang City

(Sales) +84 898 119 116 | (Service) +84 901 888 499

🔘 Việt An VP-Hà Tĩnh

03 Mai Thúc Loan, phường Kỳ Liên, Thị xã Kỳ Anh, Hà Tĩnh

(Sales & Service) +84 938 442 414