Biological filters are one of the most effective solutions for wastewater treatment. With the support of natural microorganisms, this system not only helps remove pollutants but also sustainably improves water quality. Especially when combined with automatic wastewater monitoring technology, the efficiency of treatment and water quality monitoring is further enhanced.

What is a biological filter?

Biological filters are a wastewater treatment system that relies on the activity of microorganisms adhering to the surface of filter materials. During operation, wastewater is introduced into the tank and flows through layers of solid materials where microorganisms develop into biomass communities. These microorganisms break down organic substances in the wastewater through aerobic or anaerobic processes, depending on the design and type of the filter. The treatment efficiency of the filter depends on the growth capacity of the microorganisms and the extent of contact with the wastewater, effectively purifying water in industrial and urban treatment systems.

Common types of biological filters today

Trickling Filter

Trickling filters are wastewater treatment systems based on microorganisms that adhere to and grow on a layer of filter media. Wastewater is evenly distributed over the media layer, which typically consists of gravel, stones, or plastic with sizes ranging from 25 to 100 mm. Here, the microorganisms decompose organic substances through aerobic processes.

The structure of a trickling filter typically ranges from 0.9 to 2.5 meters in height, with an average height of 1.8 meters, depending on the type of material and treatment requirements. The biofilm layer that develops on the surface of the media has a thickness of 0.1 to 0.2 mm, where microorganisms carry out the decomposition process. As the biomass increases, the oxygen consumption also rises, enhancing the treatment efficiency.

The trickling biological treatment system is divided into several types based on processing speed, including slow, medium, fast, high-speed, and coarse filters. Each type has its own characteristics regarding flow rates and methods of distributing wastewater, aimed at optimizing wastewater treatment efficiency for specific needs.

High-Load Biological Filter

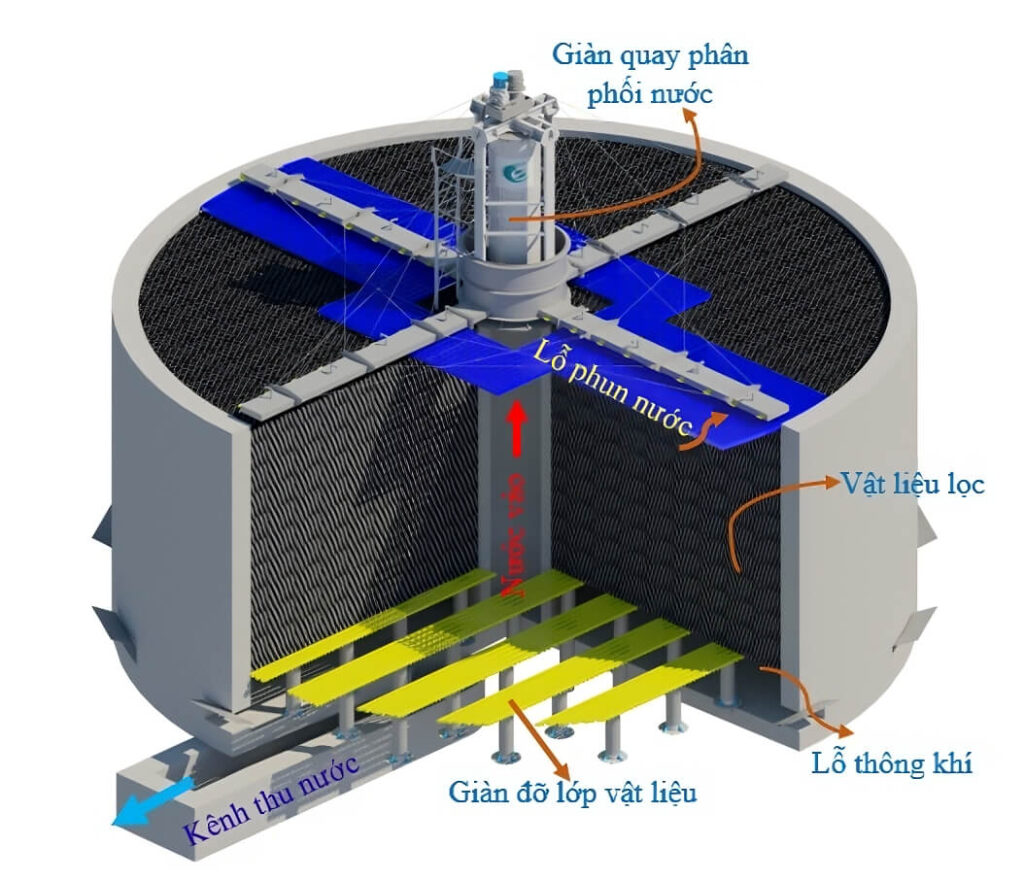

High-load biological filters are wastewater treatment systems designed to handle larger treatment capacities due to their greater height and load compared to trickling filters. Wastewater is distributed from above and sprayed down through a layer of larger filter media (40-60 mm in size), facilitating contact between the water and the microbial film. This design accelerates the oxidation of organic matter due to the wider gaps and artificial ventilation, promoting efficient treatment processes.

The structure of the tank includes the tank body, a layer of filter media, a spraying irrigation system, a water distribution system, a wastewater collection trough, and an air supply system. Before wastewater is introduced into the tank, it needs to be pre-treated to ensure that the BOD concentration does not exceed 150-200 mg/L. In cases where the BOD is higher, the wastewater needs to be diluted before treatment.

High-load biological wastewater filters are applied to effectively treat wastewater sources with high organic substance concentrations, helping to increase efficiency and meet the demands of treating more complex pollutants.

The biological filter has a layer of filter material submerged in water

Biological filters with a layer of filter material submerged in water are a wastewater treatment system with the main advantages of low operating costs and energy efficiency. In this tank, the filter material layer is completely immersed in the wastewater, allowing microorganisms to grow on the surface of the material to decompose organic matter.

However, due to the difficulty of aeration, the tank often faces oxygen deficiency, leading to lower treatment efficiency compared to other types of tanks. The tank is also prone to clogging, requiring regular maintenance and clearing. Furthermore, this filter tank is sensitive to temperature and has the potential to cause unpleasant odors if not operated and maintained properly. With its low cost, this filter is suitable for small-scale wastewater treatment systems where cost-saving is the top priority.

Biological filters with submerged filter material

Biological filters with a layer of filter material not submerged in water are a popular wastewater treatment system due to their simple design and ease of construction. This tank is typically built from modules or reinforced concrete, featuring high automation, minimal odor production, and good aesthetics.

However, the downside of this type of filter is the high loss load, which leads to a reduction in the amount of filtered water. The aeration process also requires a significant amount of energy to ensure effective treatment, as it needs to create air currents to supply oxygen. Nevertheless, retaining suspended solids during the filtration process often does not achieve high efficiency, necessitating operational adjustments to avoid the loss of solids.

Nguyên lý hoạt động bể lọc sinh học

The operating principle of biological filters with a layer of filter material not submerged in water is based on the growth of microorganisms adhering to the surface of the filter material. After preliminary treatment of the wastewater, it flows through the gaps in the filter material and comes into contact with a biofilm composed of aerobic and anaerobic microorganisms.

During this process, the microorganisms in the biofilm decompose the organic substances in the wastewater. Aerobic decomposition produces CO2 and water, while anaerobic decomposition generates methane (CH4) and CO2. When the old biofilm becomes saturated, it detaches from the surface of the material and is carried away by the water, allowing a new biofilm to form and continue the filtration process.

The treated wastewater will contain fragments of the biofilm; therefore, it needs to be directed to a settling tank to separate the suspended solids before being discharged into the environment.

Advantages of Biological Filters

- High Treatment Efficiency: Biological wastewater filters can effectively remove organic substances, nitrogen, ammonia, and phosphorus from wastewater, improving the quality of the treated water.

- Low Operating Costs: Compared to other wastewater treatment methods, microbial filters require less maintenance and operating costs due to their simple structure and easy installation.

- Short Treatment Time: The oxidation process occurs rapidly, shortening the water retention time and enhancing treatment efficiency.

- Flexibility: The water retention time and flow rate can be adjusted to adapt to changes in operating conditions.

- Low Sludge Production: Microbial treatment tanks typically produce less sludge than systems like Aerotank, reducing the need for sludge treatment.: Bể xử lý vi sinh vật thường tạo ra lượng bùn ít hơn so với các hệ thống như Aerotank, giảm nhu cầu xử lý bùn.

Disadvantages of Biological Filters

- Maintenance Difficulties: Without regular maintenance, the tank can become clogged with sludge and accumulated solids, reducing treatment efficiency.

- Unpleasant Odor: Some microbial treatment tanks may emit odors if not properly aerated, affecting the surrounding environment and causing discomfort to nearby residents.

- Space Requirements: Biological wastewater filters require relatively large areas to operate effectively, which can be a limiting factor in some cases.

- Dependence on Environmental Conditions: The performance of the filter can be affected by temperature and other environmental factors, making it challenging to maintain stable treatment efficiency.

- Need for Good Aeration Systems: To optimize the oxidation process and avoid odors, the filter requires an effective aeration system, which may increase initial investment costs.

Applications of Biological Filters

- Domestic Wastewater Treatment: Used in residential and urban areas to remove organic matter, nitrogen, and phosphorus.

- Industrial Wastewater Treatment: Utilized in food and dye manufacturing plants to treat highly contaminated wastewater.

- Agriculture: Helps treat wastewater from livestock operations, improving water quality before discharge into the environment.

- Water Reuse: Integrated into water reuse systems for irrigation and other purposes.

- Industrial Zones: Treats concentrated wastewater from multiple factories, improving the quality of discharged water.

- Healthcare Facilities: Treats wastewater containing organic and hazardous substances, protecting public health.

- Tourism Areas: Minimizes pollution from tourist activities, preserving the natural landscape.

- Households: Mini filters for onsite wastewater treatment, reducing costs and pollution.

Conclusion

Biological filters are an effective wastewater treatment system that meets environmental and legal requirements. With the capability to remove organic matter, nitrogen, and phosphorus, biological treatment systems not only contribute to improving water quality but also support agricultural, industrial, and domestic activities. Although there are some drawbacks, such as odors and space requirements, their outstanding advantages make biological wastewater filters a top choice for many wastewater treatment applications today.