What is a Steam Trap? A Detailed Overview of Steam Traps in Steam Systems

A Steam Trap is a critical component in steam systems, designed to remove condensate from pipelines without allowing steam to escape. The primary function of a steam trap is to ensure efficient system operation, conserve energy, and prevent issues in steam distribution systems caused by the accumulation of condensate.

How Steam Traps Operate

Steam traps function by distinguishing between steam and condensate. As steam passes through the system, a portion condenses into water due to heat loss. The steam trap automatically opens to discharge the condensate and closes to retain the steam. There are three common types of steam traps:

- Mechanical Steam Traps:Operate based on the density difference between steam and condensate (e.g., float traps or inverted bucket traps).

- Thermodynamic Steam Traps:Utilize pressure and temperature differences to open or close the valve.

- Thermostatic Steam Traps:Function based on the temperature difference between steam and condensate.

Challenges in Monitoring Steam Traps in Steam Systems

Monitoring steam traps is a critical task to ensure the efficiency of steam distribution systems, yet it faces significant challenges. Below are the primary issues associated with steam trap monitoring.

Research indicates that approximately 30% of steam traps in industrial systems fail annually. Failures in steam traps lead to issues such as steam loss, reduced system efficiency, and increased operational costs.

Costly Traditional Inspection Methods

Traditional steam trap inspection methods, such as using temperature or ultrasonic measurement devices, are often complex and time-consumingThese processes require skilled personnel, specialized equipment, and, in some cases, system shutdowns, which disrupt production.

Inefficient Periodic Inspection Cycles

Steam traps are typically inspected at intervals of 3, 6, or 12 monthsresulting in delayed detection of failures. During the periods between inspections, malfunctioning steam traps may go unnoticed, leading to unaddressed energy losses.

Consequences: Significant Energy Losses

Due to these challenges, 5-10% of the total energy costs in steam systems are lost as a result of leaking or malfunctioning steam traps.

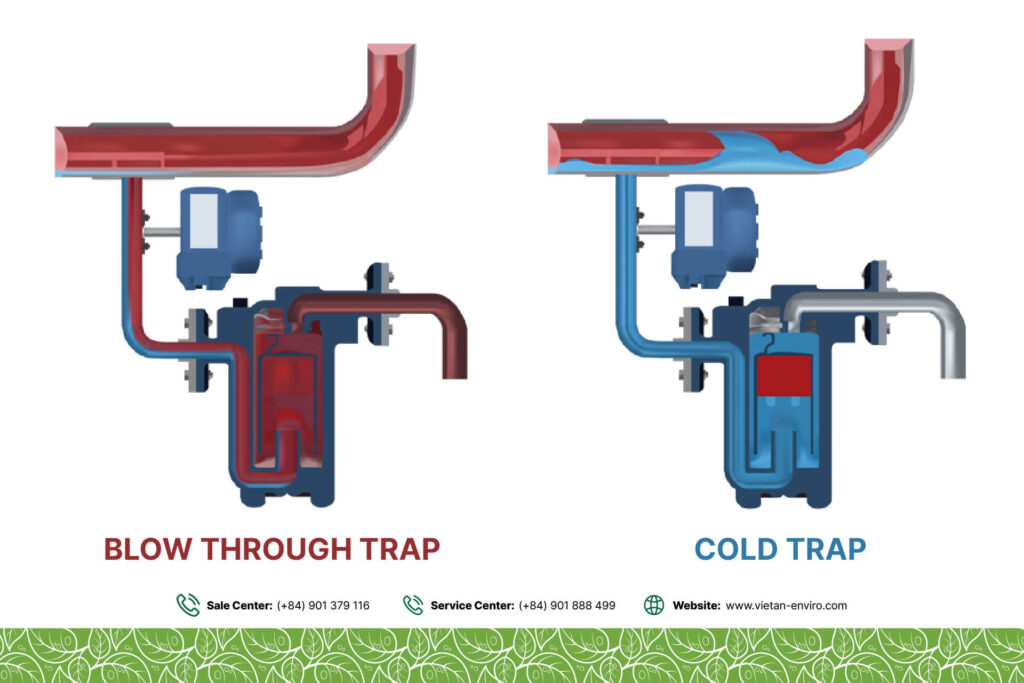

Blow Through Trap and Cold Trap in Steam Trap Systems

Blow Through Trap occurs when a steam trap fails in a continuously open state, allowing steam to escape along with condensate. This condition is commonly referred to as "blow-through" because steam passes through the trap without being retained.

Consequences of Blow Through Trap:

- Increased costs for steam procurement.

- Risk of insufficient steam supply for downstream processes.

Cold Trap occurs when a steam trap fails in a continuously closed state, preventing condensate from being discharged. As a result, condensate accumulates in the trap and flows back into the steam distribution system.

Consequences of Cold Trap:

- Water HammerIf condensate enters the steam distribution pipeline, under high pressure, it can cause water hammer, resulting in powerful impacts at locations such as elbows and tees. This can lead to damage to the pipeline and fittings, posing risks to workplace safety.

- Reduced System Efficiency: Escaping steam lowers pressure and temperature, leading to inefficient steam utilization and necessitating extended heating times.

Automated and Continuous Steam Trap Monitoring Solution from EMERSON

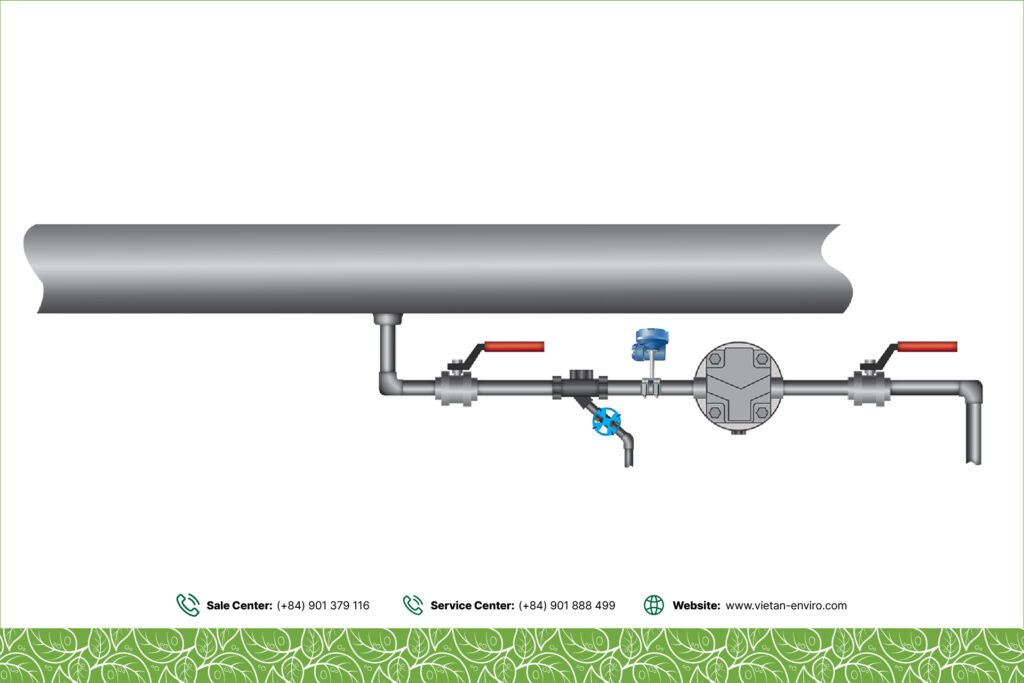

Rosemount™ 708 Wireless Acoustic Transmitter is an externally mounted device designed for monitoring steam traps and pressure relief valves (PRVs). Requiring no pipe cutting or modifications, it significantly reduces installation time and costs.

Utilizing WirelessHART® this device accurately transmits critical data, including:

- Acoustic activity of the steam trap

- Pipe temperature

- Operational status of the steam trap

Integration with Steam Trap Monitoring Softwareoperational personnel gain real-time insights into:

- The operational status of steam traps (whether functioning properly or not).

- Energy consumption levels and excess costs caused by leaks.

- Carbon emissions resulting from steam leaks.

- Data storage, management, and customizable report generation.

Benefits of Automated Steam Trap Monitoring

- Immediate detection of steam trap malfunctions.

- Reduced energy losses due to steam leaks.

- Cost and labor savings from eliminating periodic inspections.

- Enhanced steam utilization efficiency.

- Improved safety for steam distribution systems.

- Proactive maintenance, repair, and replacement planning.

Tối ưu hóa hệ thống hơi với giải pháp từ Việt An Enviro

Effective monitoring and management of steam traps are critical factors in reducing energy losses, saving costs, and enhancing the operational efficiency of steam systems.

With solutions from Emerson, businesses in Vietnam can achieve optimal steam system performance, gaining a competitive edge and promoting sustainable production.

Việt An Enviro is proud to be the official distributor of the Rosemount™ 708 Wireless Acoustic Transmitter for steam trap monitoring in Vietnam, provided by EMERSON. Contact us for professional consultation.

Việt An – Thị phần số 1 Việt Nam về Giải Pháp Quan Trắc Môi Trường và Đo Lường Công Nghiệp

🔘 Head Office (Ho Chi Minh City)

No.4E, Street 6, An Phu Ward, Thu Duc City, Ho Chi Minh City

(Sales) +84 902 970 009 | (Service) +84 901 888 499

🔘 Northern Viet An

Lô 33, khu BT4-1, khu nhà ở Trung Văn, phường Trung Văn, quận Nam Từ Liêm, Hà Nội

(Sales) +84 901 851 116 | (Service) +84 901 888 499

🔘 Central Viet An

No.5A Mai Xuan Thuong Str., Hoa Khe Ward., Thanh Khe Dist., Da Nang City

(Sales) +84 898 119 116 | (Service) +84 901 888 499

🔘 Việt An VP-Hà Tĩnh

03 Mai Thúc Loan, phường Kỳ Liên, Thị xã Kỳ Anh, Hà Tĩnh

(Sales & Service) +84 938 442 414