Except for thermal power plants and some customers who have pre-treated flue gas with dry methods such as electrostatic precipitators and fabric filters, most flue gas discharge pipes in Vietnam are wet-treated. Therefore, the flue gas has very high humidity and low temperature.

With the cold-dry sampling method, the flue gas sample is taken directly from the stack and quickly cooled to 4-40 degrees Celsius before being introduced into the analyzer.

As a result, the flue gas is highly corrosive, and the cooling technology (cold-dry) dries the flue gas, causing gases such as HCl, NH3, or SO2 to be absorbed when water is separated, so the measurement results are no longer accurate because these substances are mostly converted into liquid acids.

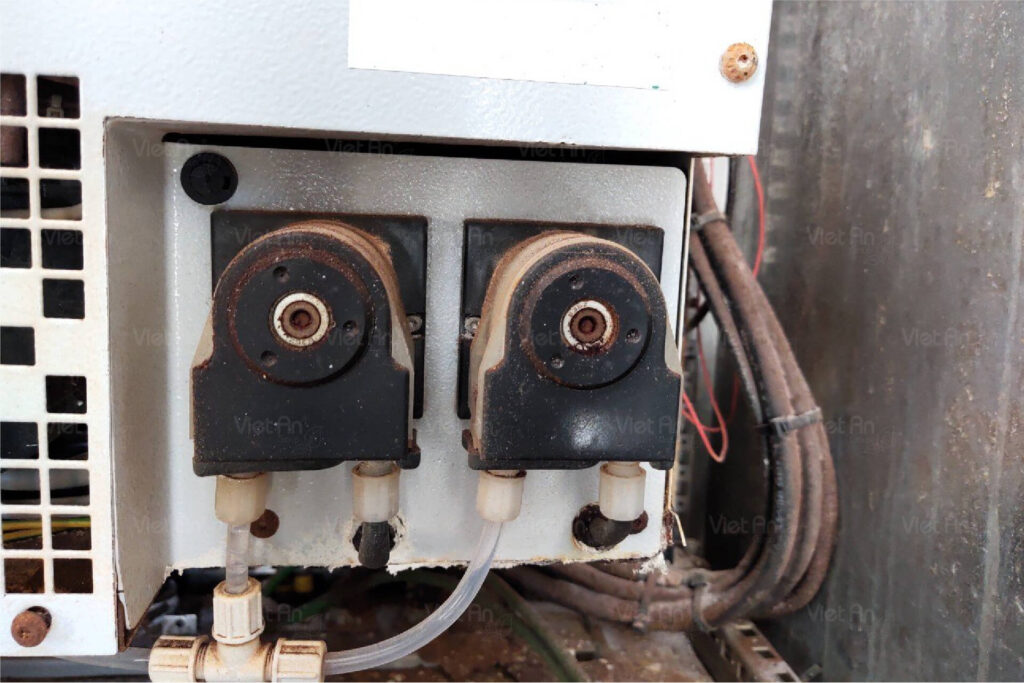

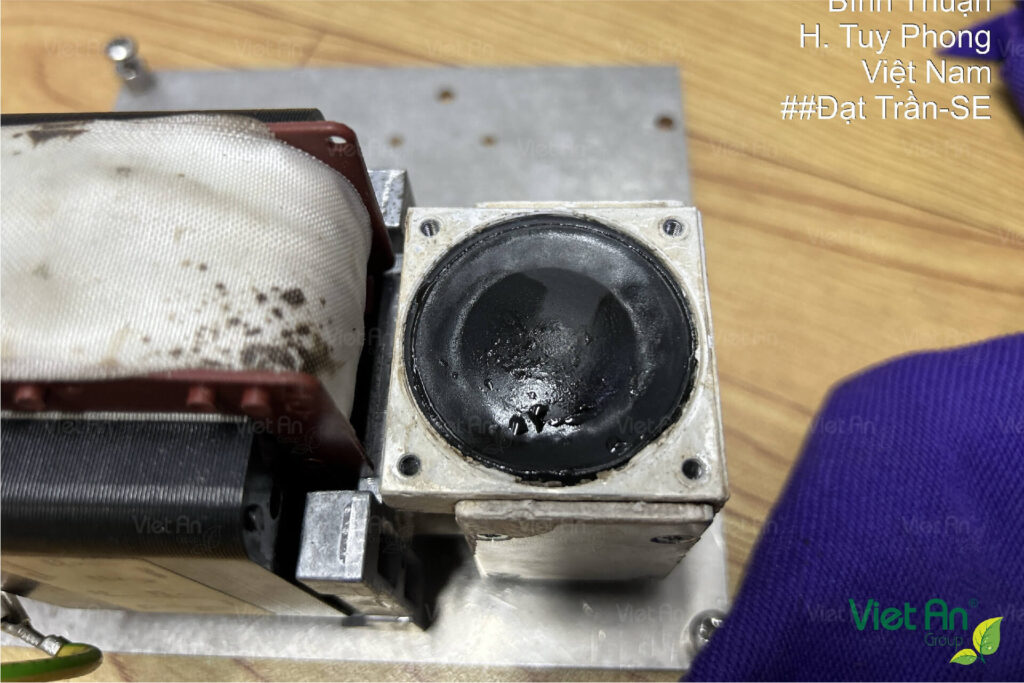

If maintenance and repair of equipment are not carried out continuously and regularly, it leads to corrosion, rust, and aging of equipment in the sampling system and gas analysis system, especially metal parts, causing equipment damage and inaccurate measurement results.

Below are some images of corroded, rusted, and aged equipment in the flue gas monitoring system. ăn mòn, rỉ sét và lão hóa.

Additionally, the cold-dry system typically consumes more energy than other sampling methods due to the need for cooling and drying systems. Operation and maintenance costs are also higher.

Therefore, the cold-dry sampling method is only suitable for flue gas with a temperature above 100°C and flue gas with dry treatment.

Flue gas sampling and transportation: The cornerstone of precise gas analysis

At air quality monitoring stations, the gas analyzers are often located far from the base of the chimneys, and the emission height is very high. Therefore, extracting and transporting the gas sample to the analyzer while maintaining its original composition compared to the gas emitted from the chimney is crucial to ensure that the analysis results accurately reflect the nature of the emissions released into the environment.

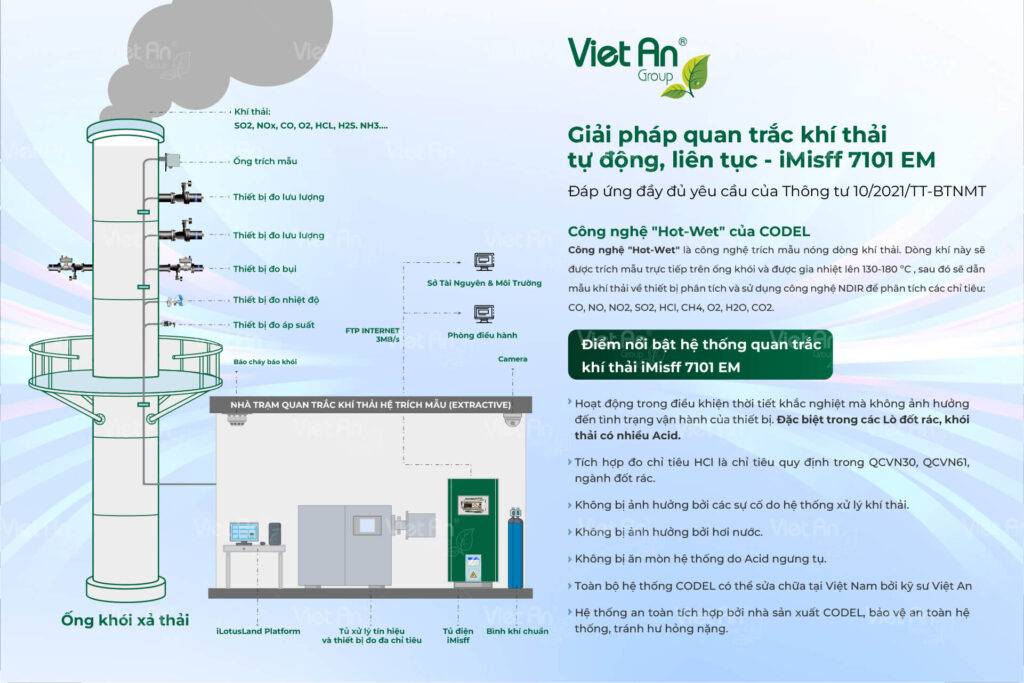

With the hot-wet sampling solution, the flue gas sample to be analyzed is directly extracted from the chimney, transported to the analyzer through a heated pipe up to 180°C, and analyzed directly in the analyzer using non-contact optical measurement technology in a single measurement chamber.

Additionally, if the flue gas sample is not heated and stabilized at 160-180°C throughout the measurement process, acidic and alkaline gases such as HCl, HF, and NH3 are likely to condense, causing errors in the analysis process and reducing the lifespan of the analytical equipment.

For difficult-to-measure flue gases containing high levels of moisture, particulate matter, and corrosives, the choice of a self-cleaning sample probe and heated tube, depending on the specific application, can ensure the flue gas analysis system operates reliably for up to 10 years with minimal maintenance.

By heating the flue gas from the sample probe to the analyzer, acid condensation that could corrode the analysis system is prevented.

Therefore, extracting and transporting the gas sample to the analyzer while maintaining its original composition compared to the gas emitted from the chimney is crucial to ensure that the analysis results accurately reflect the nature of the emissions released into the environment.

Sample Probe & Sample Lines

A sample probe is a device used to extract gas samples from emission sources. This gas sampling device can operate in environments with temperatures up to 200°C (or up to 300°C for special applications) and is equipped with filters at the sampling tip to minimize dust and impurities in the gas sample.

A sample line is a heated gas transfer line used to transport gas samples from the sampling probe to the gas analysis system.

The sample line can heat the flue gas from 30°C to 400°C to prevent moisture condensation in the gas sample. These two components are crucial in the gas sampling and transportation process to the analyzer. Việt An has carefully selected the optimal solution from PSG (Perfect Sample Gas), a German expert in providing gas sampling probes and heated transfer lines, to maximize our customers' investment.

Discover more about PSG (Perfect Sample Gas)

Advantages and disadvantages between Hot-Wet and Cold Dry technologies

| Features | Cold Dry CEMS | Hot Wet CEMS |

| Sample handling |

|

|

| Temperature | The gas needs to be cooled before measurement, which can lead to the condensation of some gases with high dew points. | Maintains a high temperature (approximately 180°C or higher) throughout the system. |

| Humidity | Removing moisture can affect the measurement of water-soluble gases. | Maintains moisture content from the chimney to the analyzer and discharge point. |

| Suitability | Use if the Hot Wet method is not preferred or to avoid using long heated sampling lines. | Suitable for monitoring water-soluble gases or gases that form corrosive acids. |

| Maintenance cost | Maintenance costs are higher than for Hot Wet systems. The analyzer must be placed in a continuously air-conditioned station. | Lower maintenance costs. |

| Initial investment | Low | High |

| Reliability & Accuracy | Accuracy is lower due to the removal of water-soluble components during cooling. | Higher reliability and accuracy due to less sample handling. |

Reasons for the continued use of Cold-Dry technology in Vietnam

Low capital expenditure: Compared to other flue gas sampling technologies, Cold-Dry sampling systems have lower initial investment and operating costs. This makes them an attractive option for businesses with limited budgets, especially small and medium-sized enterprises.

Misguided technology advice: Consulting firms providing air monitoring station installation services may not recommend the most suitable technology for a business's specific industry, or some businesses may be unaware of other flue gas sampling methods or lack the information to evaluate the advantages and disadvantages of each method.

Choosing the optimal flue gas sampling method for automated air monitoring stations to meet the requirements of Circular 10/2021/TT-BTNMT.

Select an appropriate automatic flue gas monitoring solution that suits the measurement application and complies with Circular 10/2021/TT-BTNMT. To ensure optimal investment, operation, and enhance the company's reputation in environmental protection.

With over 300 installed air monitoring stations, Viet An has found that the Hot-Wet sampling solution is the optimal solution for flue gas measurement in most industries in Vietnam.

Viet An Group, with over 10 years of experience in "Air Monitoring Station Installation," is confident in providing you with a complete, long-term solution and ensuring optimal investment, operation, and enhancing the company's reputation in environmental protection. Please get in touch with us for the most suitable solution!

Discover more about iMisff 7101 EM – Giải pháp quan trắc khí thải tự động, liên tục.

Việt An – Thị phần số 1 Việt Nam về Giải Pháp Quan Trắc Môi Trường và Đo Lường Công Nghiệp

🔘 Head Office (Ho Chi Minh City)

No.4E, Street 6, An Phu Ward, Thu Duc City, Ho Chi Minh City

(Sales) +84 902 970 009 | (Service) +84 901 888 499

🔘 Northern Viet An

Lô 33, khu BT4-1, khu nhà ở Trung Văn, phường Trung Văn, quận Nam Từ Liêm, Hà Nội

(Sales) +84 901 851 116 | (Service) +84 901 888 499

🔘 Central Viet An

No.5A Mai Xuan Thuong Str., Hoa Khe Ward., Thanh Khe Dist., Da Nang City

(Sales) +84 898 119 116 | (Service) +84 901 888 499

🔘 Việt An VP-Hà Tĩnh

03 Mai Thúc Loan, phường Kỳ Liên, Thị xã Kỳ Anh, Hà Tĩnh

(Sales & Service) +84 938 442 414