Vibrating Fork Level Sensors provide accurate, reliable, and efficient measurement solutions, meeting the diverse needs of industrial applications.

Featuring advanced technology, these sensors not only optimize production processes but also enhance performance and reduce operational costs, particularly in liquid and solid level measurement applications.

From harsh environments involving corrosive, viscous liquids or high temperatures to simpler applications, Emerson’s level sensors consistently deliver superior performance. Below are the main types of level sensors and their operating principles.

Continuous Level Measurement

With superior accuracy, intelligent design, and robust performance under all conditions – from extreme environments to corrosive liquids.

These sensors not only enable perfect process control but also elevate safety and efficiency.

Let Emerson Rosemount take your level measurement technology to the next level! Explore the measurement principles of Emerson’s sensors below.

1. Hydrostatic Pressure / Differential Pressure Level Sensors

Vibrating Fork Level Sensors operate based on the principle of hydrostatic pressure, which correlates the pressure at a point in a liquid to the height of the liquid column above, influenced by the liquid’s density and gravitational acceleration.

Ideal for measuring water or liquid and solid level in open or closed tanks, even in harsh environments with high temperatures, high pressures, or corrosive liquids.

Advantages:

- Integrated on-site display and configuration, with Bluetooth connectivity support.

- Tuned-System design with a diaphragm seal isolating the process medium, improving response time by nearly twofold.

- Equipped with device diagnostics features such as Basic Diagnostics, Loop Integrity, Process Intelligence, and Plugged Impulse Line, ensuring sensor reliability.

- Unlimited measurement range with an accuracy of 0.025% of the span.

- Adjustable turndown ratio up to 200:1, enhancing accuracy for low-level water measurement applications. water ở mức thấp.

2. Guided Wave Radar Level Sensors

Vibrating Fork Level Sensors utilize high-frequency radar waves transmitted along a probe or rod. When the radar waves encounter the surface of a liquid or solid, a portion of the energy is reflected back, enabling precise level calculation.

These sensors are ideal for narrow tanks, confined spaces, or media with low dielectric constants.

Advantages:

- Accurate measurement unaffected by changes in temperature, density, or vibration, making them ideal for liquid and solid level measurements.

- Dual-compartment housing separates signal connections from control circuits, minimizing moisture or water accumulation that could cause damage.

- Easy installation and configuration via the HART Communication Protocol.

- Probes can be easily trimmed to fit the actual tank size.

- Suitable for challenging applications, including liquids, slurries, solids, multiphase media, and environments requiring high explosion safety, such as oil, gas, and chemical industries.

3. Non-Contact FMCW Radar Level Sensors

Vibrating Fork Level Sensors employ continuous frequency-modulated radar technology. Reflected radar waves from the material surface determine the distance to the surface, making them suitable for liquid and solid level measurements in tanks with agitators, corrosive media, or high dust levels. liquid and solid level và chất rắn trong các bồn có cánh khuấy, môi chất ăn mòn, hoặc nhiều bụi.

Advantages:

- PVDF or PTFE housing materials and up to IP68 protection make these sensors suitable for most industrial liquid level measurement applications, from harsh conditions to highly corrosive environments.

- Measurement range up to 30 meters.

- Smart Meter Verification feature automatically checks device health under operating conditions and generates reports for planned maintenance.

- Easy calibration without altering water levels, enhancing efficiency for water level measurement applications.

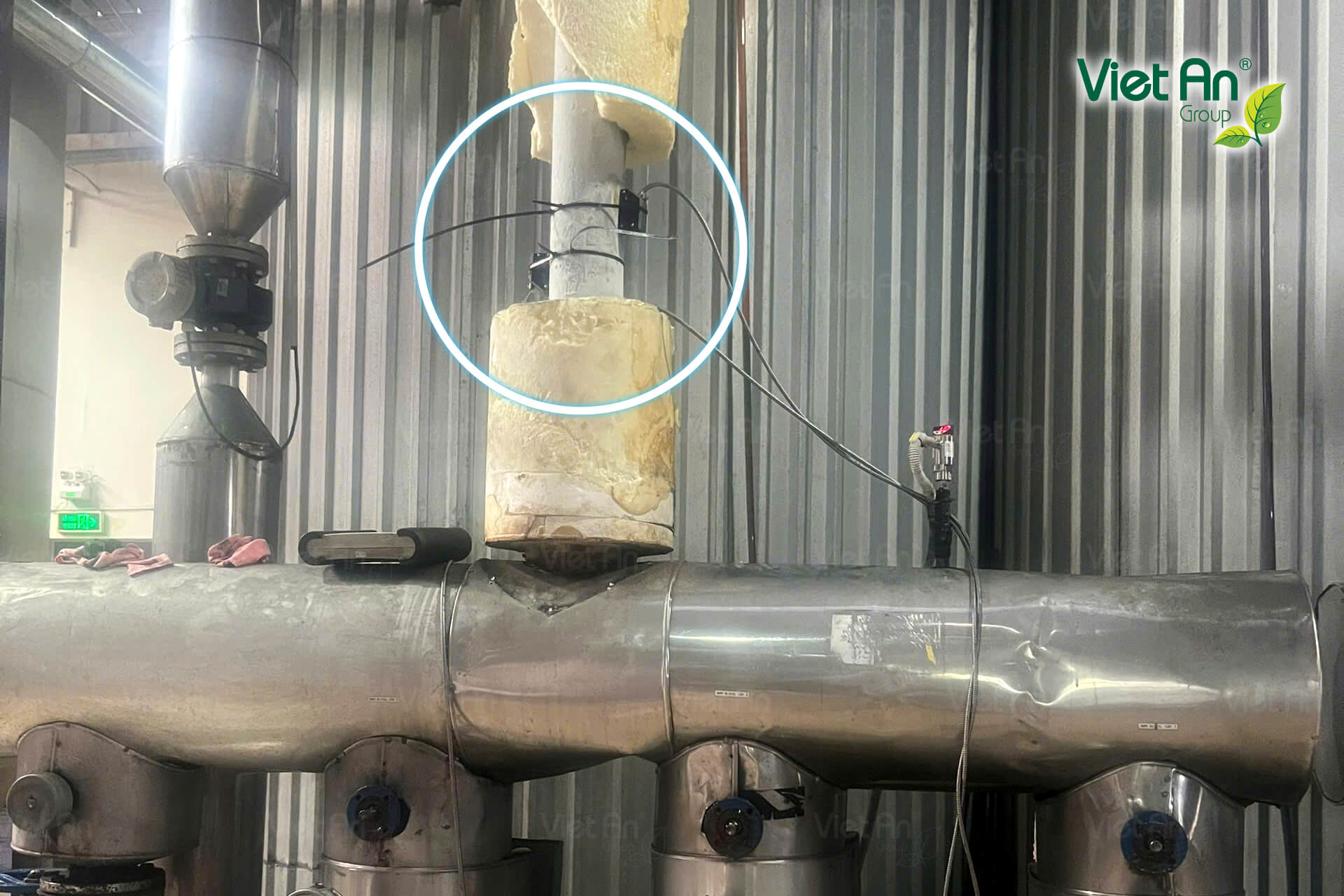

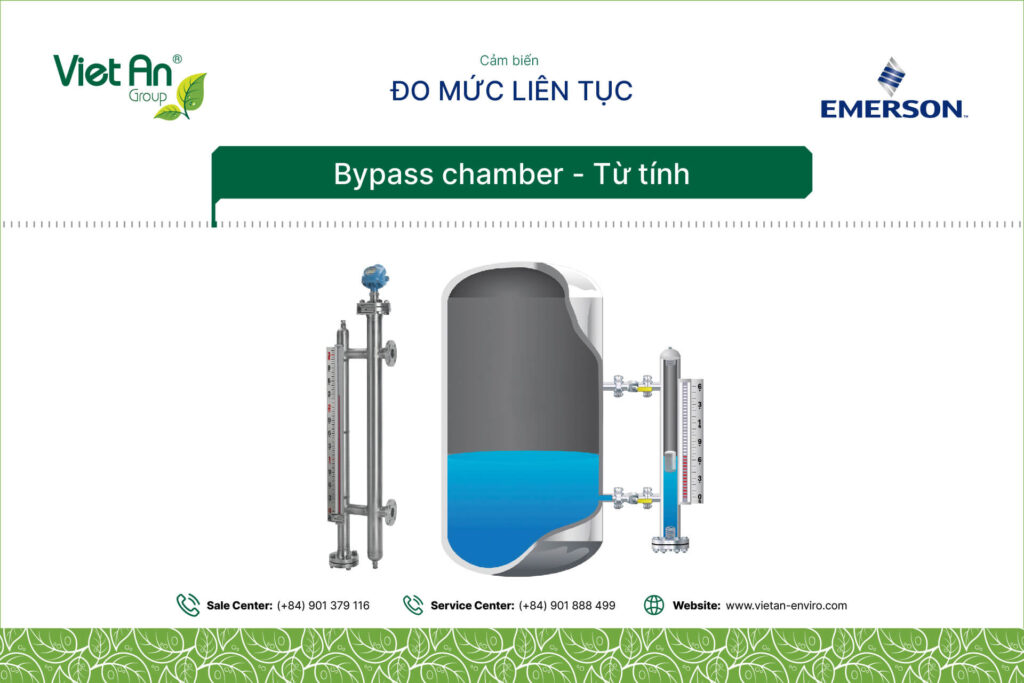

Magnetic Float Level Sensors - Bypass chamber

Magnetic float level sensors use a magnetic float that moves with the liquid level in a bypass tube, transmitting signals to a magnetic field sensor to display the level point. This provides an intuitive solution for liquid level measurement in small tanks or with corrosive chemicals. The non-contact sight glass design minimizes leakage risks compared to traditional sight glass gauges. liquid and solid level trong bồn nhỏ, hóa chất ăn mòn.

Advantages:

- The glass design does not come into contact with the medium, minimizing leakage compared to traditional glass watches.

- Measurement range up to 30 meters.

- Can be integrated with radar level sensors for data transmission.

- Suitable for applications measuring the interface of two liquids or liquid and gas mixtures.

Point Level Sensors

Point Level Sensors of EMERSON are the optimal choice for simple yet effective applications, accurately detecting when liquids or solids reach predetermined thresholds in harsh environments.

Emerson point level sensors operate based on three measurement principles as follows:

1. Rotating Paddle Level Sensors

Vibrating Fork Level Sensors utilize a motor-driven paddle. When material contacts the paddle, the motor stops or slows, signaling a full or empty level. These sensors are ideal for detecting solid material levels, such as powders or granules, in high-temperature or high-humidity environments.

Advantages:

- Robust paddle design withstands heavy loads and extreme temperatures.

- Unaffected by dust, static electricity, buildup, or clumping.

- Insertion length options range from 70 mm to 4,000 mm.

- Fully sealed motor bearings and shaft, making it ideal for dusty applications.

- Rotatable protective housing facilitates easy installation and optimizes space utilization.

2. Vibrating Fork Level Sensors

Vibrating Fork Level Sensors use two prongs oscillating at a fixed frequency. When material covers the prongs, the frequency changes, signaling the level. liquid and solid level are suitable for environments with vibration, corrosion, or abrasion.

Advantages:

- Short fork design enables installation in small pipes or tanks with highly restricted space.

- Extendable length options withstand high mechanical loads, such as low-level indication in very large or tall silos.

- Sensitivity can be customized to high or low settings based on the application.

- Multiple sensitivity levels available: 5 g/L, 20 g/L, 50 g/L.

- Housing protection rating up to IP67, providing excellent resistance to dust and moisture.

3. Vibrating Rod and Capacitance Level Sensors

Vibrating Rod:: Vibrating Fork Level Sensors use a single rod that generates oscillations. When solid material contacts the rod, the oscillation diminishes, signaling the level. These are suitable for basic solid level measurement applications.

- Suitable for basic solid material measurement applications.

Capacitance: Capacitance level sensors measure levels based on changes in capacitance between the sensor and the tank wall, suitable for both liquid and solid level measurements with dielectric constants as low as 1.5.

- An optimal solution for most production process applications to measure the level of solids with a recommended dielectric constant.

Advantages:

- Sensitivity can be customized to high or low settings based on the application.

- Extendable length options withstand high mechanical loads, such as low-level indication in very large or tall silos.

- Housing protection rating up to IP67, offering excellent resistance to dust and moisture.

- Capable of measuring media with a dielectric constant as low as 1.5.

Applications of Emerson Level Sensors: From Basic to Complex

Emerson level sensors provide flexible solutions for a wide range of needs, from basic to highly complex applications.

They enable easy monitoring of liquid or solid levels in applications such as:

- Level measurement for distillation columns.

- Measuring the level of cooked grains in fermentation silos for cereal production.

- Level monitoring in fly ash silos at coal-fired power plants.

- Level measurement for Clean-in-Place (CIP) solutions in the dairy industry.

- Level monitoring in chemical storage tanks.

- Measuring dust collector tank levels in limestone production.

- Monitoring sugar stock levels for cereal manufacturing.

- Level measurement in buffer tanks and pressure vessels.

- Level monitoring for three-phase separators.

- Measuring levels during evaporation and crystallization processes in sugar refining.

- Level monitoring in milk storage tanks.

- Level measurement in residual oil tanks.

- Level monitoring in reactors and mixing vessels.

- Level measurement for two-phase separators.

Vibrating Fork Level Sensors are designed to deliver precise measurements for both liquid and solid levels in applications ranging from the simplest to the most complex, including tanks with agitators, corrosive media, buildup, high dust, foaming, or unevenly distributed convex or concave media.

Beyond that, the Rosemount™ series of sensors are easily installed in narrow, small, or space-constrained tanks.

Ensuring smooth customer processes with the exceptional accuracy and reliability of Emerson-level sensors.

——————————————

Việt An – Thị phần số 1 Việt Nam về Giải Pháp Quan Trắc Môi Trường và Đo Lường Công Nghiệp

🔘 Head Office (Ho Chi Minh City)

No.4E, Street 6, An Phu Ward, Thu Duc City, Ho Chi Minh City

(Sales) +84 902 970 009 | (Service) +84 901 888 499

🔘 Northern Viet An

Lô 33, khu BT4-1, khu nhà ở Trung Văn, phường Trung Văn, quận Nam Từ Liêm, Hà Nội

(Sales) +84 901 851 116 | (Service) +84 901 888 499

🔘 Central Viet An

No.5A Mai Xuan Thuong Str., Hoa Khe Ward., Thanh Khe Dist., Da Nang City

(Sales) +84 898 119 116 | (Service) +84 901 888 499

🔘 Việt An VP-Hà Tĩnh

03 Mai Thúc Loan, phường Kỳ Liên, Thị xã Kỳ Anh, Hà Tĩnh

(Sales & Service) +84 938 442 414