Giới thiệu về vai trò của Oxy dư trong lò hơi

Trong bối cảnh chi phí năng lượng ngày càng tăng cao và yêu cầu về bảo vệ môi trường trở nên cấp thiết, tối ưu hóa hiệu suất lò hơi không chỉ là một lựa chọn mà còn là yếu tố sống còn đối với các doanh nghiệp sản xuất tại Việt Nam.

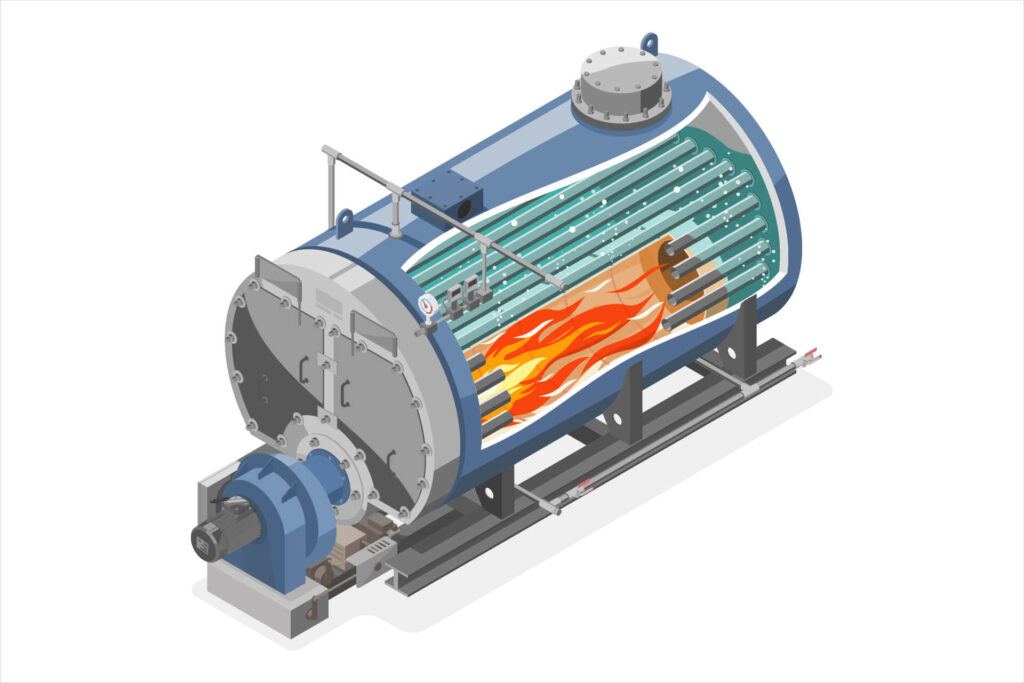

Lò hơi, được xem như trái tim của nhiều nhà máy, đóng vai trò quan trọng trong việc đảm bảo hiệu quả vận hành lò hơi và tối ưu hóa chi phí sản xuất.

Một trong những yếu tố cốt lõi để đạt được điều này là kiểm soát oxy dư trong lò hơi, giúp cải thiện quá trình đốt cháy, giảm phát thải khí độc hại và tiết kiệm năng lượng. Bài viết này sẽ phân tích tầm quan trọng của việc kiểm soát oxy, các giải pháp công nghệ tiên tiến, và lợi ích mà doanh nghiệp có thể đạt được khi áp dụng giải pháp tối ưu hóa lò hơi.

Tại sao kiểm soát Oxy lại quan trọng đến hiệu suất của lò hơi?

Kiểm soát oxy dư trong lò hơi không chỉ ảnh hưởng đến hiệu suất đốt cháy mà còn tác động đến ba khía cạnh chính:

- Tiết kiệm chi phí vận hành: Lò hơi tiêu thụ một lượng lớn nhiên liệu như than, dầu, gas hoặc sinh khối. Một sự sụt giảm nhỏ trong optimizing boiler efficiency, có thể dẫn đến lãng phí hàng tỷ đồng mỗi năm. Kiểm soát oxy ở mức lý tưởng giúp giảm thiểu tổn thất nhiên liệu và tối ưu hóa chi phí.

- Environmental Protection:: Quá trình đốt cháy không hiệu quả làm tăng lượng phát thải khí độc hại như NOx, CO và bụi, gây ô nhiễm môi trường và vi phạm các quy định khí thải tại Việt Nam. Giảm phát thải khí độc hại là mục tiêu quan trọng để doanh nghiệp xây dựng hình ảnh thân thiện với môi trường.

- An toàn và tuổi thọ thiết bị: Lò hơi hoạt động kém hiệu quả dễ gặp sự cố, hỏng hóc, gây nguy cơ mất an toàn lao động. Việc tăng tuổi thọ lò hơi thông qua kiểm soát oxy giúp giảm chi phí bảo trì và đảm bảo vận hành ổn định.

1. Kiểm soát Oxy dư trong quá trình đốt cháy

The oxygen level in a boiler’s combustion chamber must be maintained within an optimal range to ensure complete fuel combustion.Without proper control, the following issues may arise:

- Excess Oxygen (O₂)::

- Quá nhiều không khí trong buồng đốt làm giảm hiệu quả thu hồi nhiệt lò hơi, gây lãng phí năng lượng.

- Tăng phát thải NOx, vi phạm các tiêu chuẩn khí thải và ảnh hưởng đến môi trường.

- Làm tăng chi phí vận hành do tiêu hao nhiên liệu không cần thiết.

- Insufficient Oxygen::

- Gây đốt cháy không hoàn toàn, sản sinh khí CO độc hại, làm tăng nguy cơ cháy nổ và ăn mòn thiết bị.

- Reduce methane emissions by hiệu suất đốt cháy lò hơi, dẫn đến tổn thất nhiên liệu và ảnh hưởng sức khỏe người vận hành.

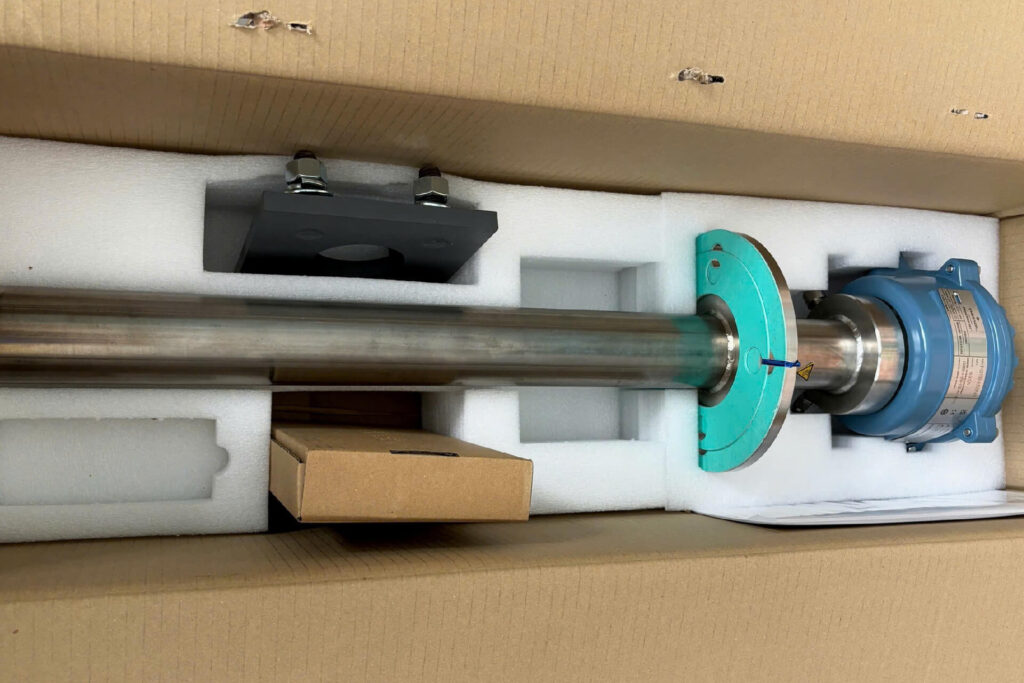

Solution: Để đạt được hiệu suất lò hơi tối ưu, lượng oxy dư nên được duy trì ở mức 0.5% đến 2%. Các giải pháp công nghệ hiện đại, như the Rosemount™ 6888A In Situ Oxygen Analyzer của Emerson, cung cấp khả năng đo lường chính xác và phản hồi nhanh chóng, giúp điều chỉnh quá trình đốt cháy hiệu quả hơn.

Lợi ích vượt trội từ việc tối ưu hóa hiệu suất lò hơi

Việc áp dụng các giải pháp kiểm soát oxy lò hơi mang lại nhiều lợi ích vượt trội:

- Tiết kiệm năng lượng lò hơi và giảm chi phí nhiên liệu đáng kể (có thể lên đến 5-15% tùy vào tình trạng ban đầu).

- Giảm phát thải NOx, CO và bụi, giúp doanh nghiệp tuân thủ các quy định môi trường và xây dựng hình ảnh thân thiện với môi trường.

- Nâng cao an toàn vận hành lò hơi, giảm thiểu rủi ro sự cố và tai nạn lao động.

- Tăng tuổi thọ lò hơi và các thiết bị liên quan, giảm chi phí bảo trì, sửa chữa.

- Ổn định chất lượng hơi, đảm bảo quá trình sản xuất diễn ra liên tục và hiệu quả.

Giải pháp kiểm soát Oxy từ Emerson

Để hỗ trợ các doanh nghiệp đạt được hiệu suất lò hơi tối ưu, Emerson cung cấp Cảm biến đo Oxy liên tục Rosemount™ 6888A In Situ Oxygen Analyzer với các đặc điểm nổi bật:

- Fast Response Time: Chỉ 8 giây, giúp điều chỉnh quá trình đốt cháy kịp thời.

- Hoạt động ổn định ở nhiệt độ cao: Lên đến 1050°C, phù hợp với nhiều loại lò hơi công nghiệp.

- Hiệu chuẩn dễ dàng: Có thể thực hiện ngay cả khi lò đang hoạt động, giảm thời gian dừng máy.

- Bảo trì thuận tiện: Thay thế và sửa chữa đầu probe tại chỗ, tiết kiệm thời gian và chi phí.

- High Accuracy:: ±0.75% giá trị đọc hoặc ±0.05% O2, đảm bảo dữ liệu đáng tin cậy.

Optimize Boiler Performance with Việt An Enviro

Controlling oxygen levels in boilers is not only key tối ưu hóa hiệu lò hơi but also a critical step in protecting the environment and reducing operational costs.

With solutions from Emerson, businesses in Vietnam can achieve enhanced boiler performance, contribute to environmental protection, and strengthen their competitive edge through sustainable production.

with Viet An Enviro,, đơn vị phân phối chính thức Cảm biến đo Oxy Rosemount™ 6888A tại Việt Nam, cam kết mang đến giải pháp tối ưu và dịch vụ chuyên nghiệp. Liên hệ ngay để nhận tư vấn chi tiết và triển khai các giải pháp tối ưu hóa hiệu suất lò hơi phù hợp với doanh nghiệp của bạn.

Việt An – Thị phần số 1 Việt Nam về Giải Pháp Quan Trắc Môi Trường và Đo Lường Công Nghiệp

🔘 Head Office (Ho Chi Minh City)

No.4E, Street 6, An Phu Ward, Thu Duc City, Ho Chi Minh City

(Sales) +84 902 970 009 | (Service) +84 901 888 499

🔘 Northern Viet An

Lô 33, khu BT4-1, khu nhà ở Trung Văn, phường Trung Văn, quận Nam Từ Liêm, Hà Nội

(Sales) +84 901 851 116 | (Service) +84 901 888 499

🔘 Central Viet An

No.5A Mai Xuan Thuong Str., Hoa Khe Ward., Thanh Khe Dist., Da Nang City

(Sales) +84 898 119 116 | (Service) +84 901 888 499

🔘 Việt An VP-Hà Tĩnh

03 Mai Thúc Loan, phường Kỳ Liên, Thị xã Kỳ Anh, Hà Tĩnh

(Sales & Service) +84 938 442 414