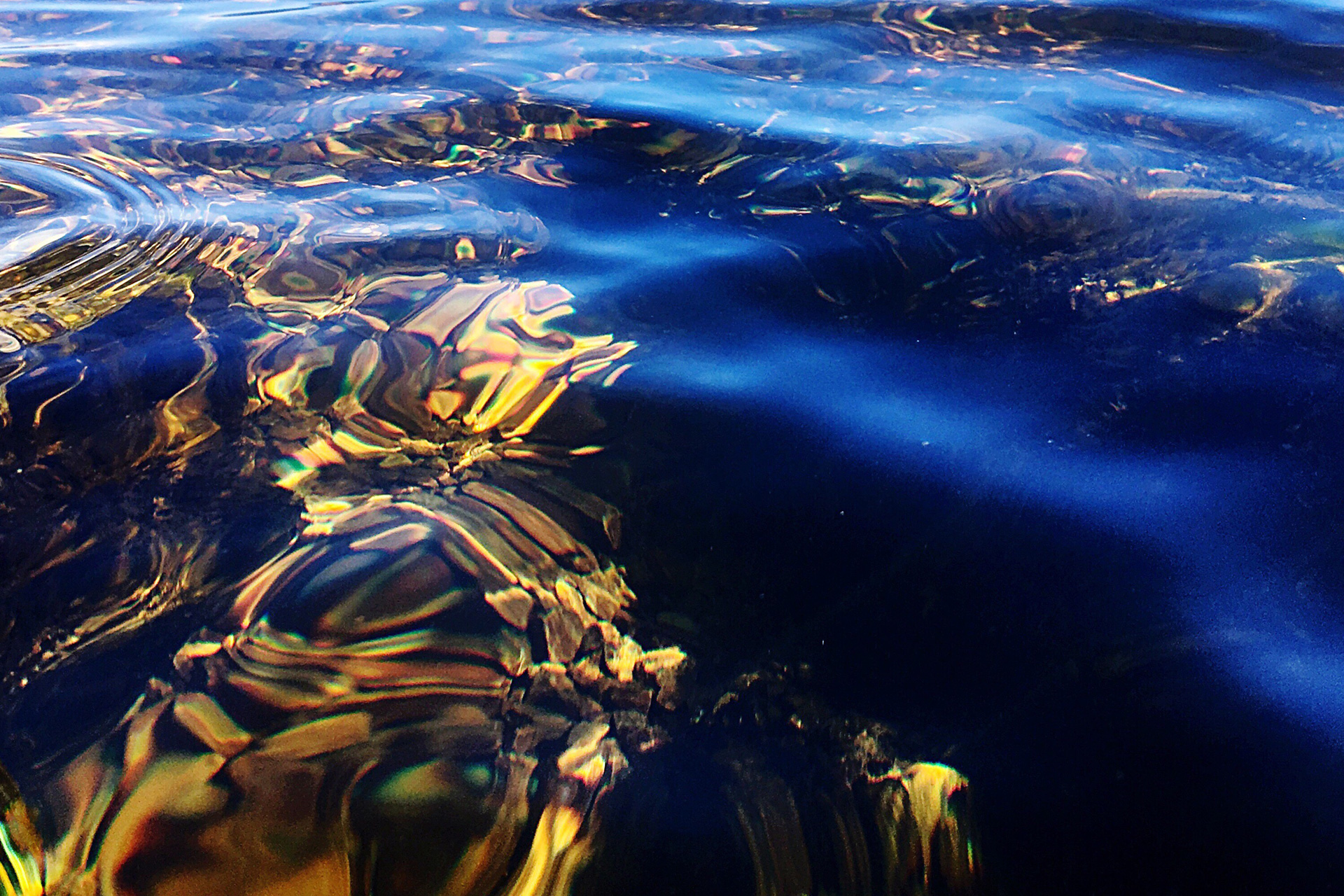

Detecting oil slicks on the water surface, especially in raw water sources, is a pressing issue for water supply plants. Oil is a complex pollutant that is difficult to treat and completely remove from water.

Oil contamination in water not only disrupts water treatment but also poses a significant threat to human health. Early and automated detection of oil spills is essential to prevent pollution and protect public health.

Tác gại của váng dầu trong nguồn nước

Oil is a particularly serious pollutant when present in raw water sources. It not only causes unpleasant odors but also reduces water quality, harms ecosystems, and endangers human health.

In terms of health, the chemicals and heavy metals in oil can cause cancer, endocrine disorders, and skin and respiratory problems when people come into contact with or consume contaminated water. For water treatment processes, oil causes many difficulties, clogging equipment and increasing operating costs.

Therefore, for a water supply plant using surface water, how to quickly detect oil slicks on the water surface, even with very small amounts of oil, is crucial to take timely action before the water enters the treatment process. váng dầu trên mặt nước dù là với lượng dầu rất nhỏ để kịp thời hành động trước khi đưa vào quy trình xử lý nước cấp.

Nhận thấy đây là một vấn đề cực kì quan trọng, Việt An đã trình bày giải pháp đến khách hàng để phát hiện nhanh chóng váng dầu từ độ cao tới 10m so với mặt nước mà không cần đến sự giám sát của con người.

This device operates based on UV principles and detects any oil slicks, from diesel to vegetable oils and even jet fuel.

When detecting oil on the water surface, this device will quickly send an alert through the plant's SCADA system or through the IoT Platform iLotusLand. This helps the plant's operators to quickly detect oil spills, stop the pumping system, and respond promptly to the incident.

Thiết bị phát hiện váng dầu LDI ROW Aluminum: Giải Pháp Tối Ưu

Recognizing the importance of this issue, Viet An introduces the LDI ROW Aluminum oil film detector for water surface detection. This device is designed to operate automatically and continuously 24/7, even in harsh environmental conditions.

Operating Principle

The LDI ROW Aluminum device operates based on UV detection. A UV LED beam excites the oil molecules in the water, producing natural fluorescence. A telescope within the system collects this fluorescence signal and transmits it to the controller for data processing. The received signal is analyzed immediately, allowing for real-time detection and alerting of oil presence on the water surface.

Outstanding Advantages

- Hoạt Động Liên Tục 24/7: Thiết bị phát hiện váng dầu trên mặt nước có khả năng hoạt động liên tục, bất kể ngày hay đêm, và trong các điều kiện môi trường khắc nghiệt.

- No human supervision: The device operates fully automatically, minimizing the need for human supervision.

- High sensitivity: Capable of detecting oil films as thick as 1 µm, ensuring high sensitivity and accuracy.

- Non-contact: The device uses a non-contact measurement principle, making it easy to install, free from fouling, and requiring minimal maintenance.

Ứng dụng rộng rãi

Thiết bị LDI ROW Aluminum có khả năng phát hiện nhiều loại dầu khác nhau như dầu động cơ, dầu tuabin, dầu thực vật, dầu bôi trơn, dầu thủy lực, dầu khoáng, dầu hàng hải, nhiên liệu & dầu thô, dầu truyền nhiệt, dầu diesel, xăng, dầu hỏa và nhiên liệu máy bay (JetA). Điều này làm cho thiết bị trở thành giải pháp lý tưởng để phát hiện váng dầu trên mặt nước cho các ngành cấp nước và công nghiệp.

Liên Hệ Tư Vấn Giải Pháp

For more information about Việt An Enviro's environmental monitoring solutions, please contact us at:

Việt An – Thị phần số 1 Việt Nam về Giải Pháp Quan Trắc Môi Trường và Đo Lường Công Nghiệp

🔘 Head Office (Ho Chi Minh City)

No.4E, Street 6, An Phu Ward, Thu Duc City, Ho Chi Minh City

(Sales) +84 902 970 009 | (Service) +84 901 888 499

🔘 Northern Viet An

Lô 33, khu BT4-1, khu nhà ở Trung Văn, phường Trung Văn, quận Nam Từ Liêm, Hà Nội

(Sales) +84 901 851 116 | (Service) +84 901 888 499

🔘 Central Viet An

No.5A Mai Xuan Thuong Str., Hoa Khe Ward., Thanh Khe Dist., Da Nang City

(Sales) +84 898 119 116 | (Service) +84 901 888 499

🔘 Việt An VP-Hà Tĩnh

03 Mai Thúc Loan, phường Kỳ Liên, Thị xã Kỳ Anh, Hà Tĩnh

(Sales & Service) +84 938 442 414