Significance of gas sample extraction and conveyance

Automated emissions monitoring systems continuously monitor the concentration of air pollutants and provide accurate data to assess compliance with environmental regulations. According to Circular 10/2021/TT-BTNMT,the installation of automated, continuous air quality monitoring stations is a mandatory requirement for effective and transparent emissions monitoring

Để đảm bảo kết quả phân tích khí thải phản ánh chính xác hiệu quả của các biện pháp kiểm soát ô nhiễm khí thải. Việc trích mẫu khí thải từ các ống khói và dẫn mẫu khí thải về đến mấy phân tích phải đảm bảo tính đại diện của mẫu khí mà thay đổi thành phần hóa học.

Vì các ống khói có thiết kế đặc thù, ống khói cao và nhà trạm đặt thiết bị phân tích khí thải đặt cách xa vị trí chân cột ống khói. Vì vậy, việc trích và dẫn mẫu khí thải về đến máy phân tích mà vẫn giữ được nguyên bản so với khí thải ra từ ống khói là vô cùng quan trọng để đảm bảo kết quả phân tích phản ánh đúng bản chất khí thải ra ngoài môi trường.

Nếu không làm tốt điều này, sẽ dẫn đến việc đánh giá sai kết quả phân tích khí thải và nặng hơn sẽ dẫn đến việc bị cơ quan chức năng phạt.

What is the most critical factor for accurate gas analysis?

In air emissions monitoring, sample extraction and gas conduction are two crucial factors that determine the accuracy of the analysis process. If this process is not performed correctly, the analysis results will be biased, leading to misjudgments about the system's pollution level and treatment efficiency. So, why is sample extraction and gas conduction so important? Let's find out!

The gas sample extraction process must ensure that the collected sample is representative of all the parameters to be analyzed in the flue gas. If the sample is not representative enough, the analysis results will not accurately reflect the flue gas condition at the emission stack.

After collecting the gas sample, we must transport it to the machine that analyzes it. This process is also critical. If the gas cools down too much during this trip and forms liquid, it can change the amounts of different pollutants in the sample. This means the results of the analysis won't be correct.

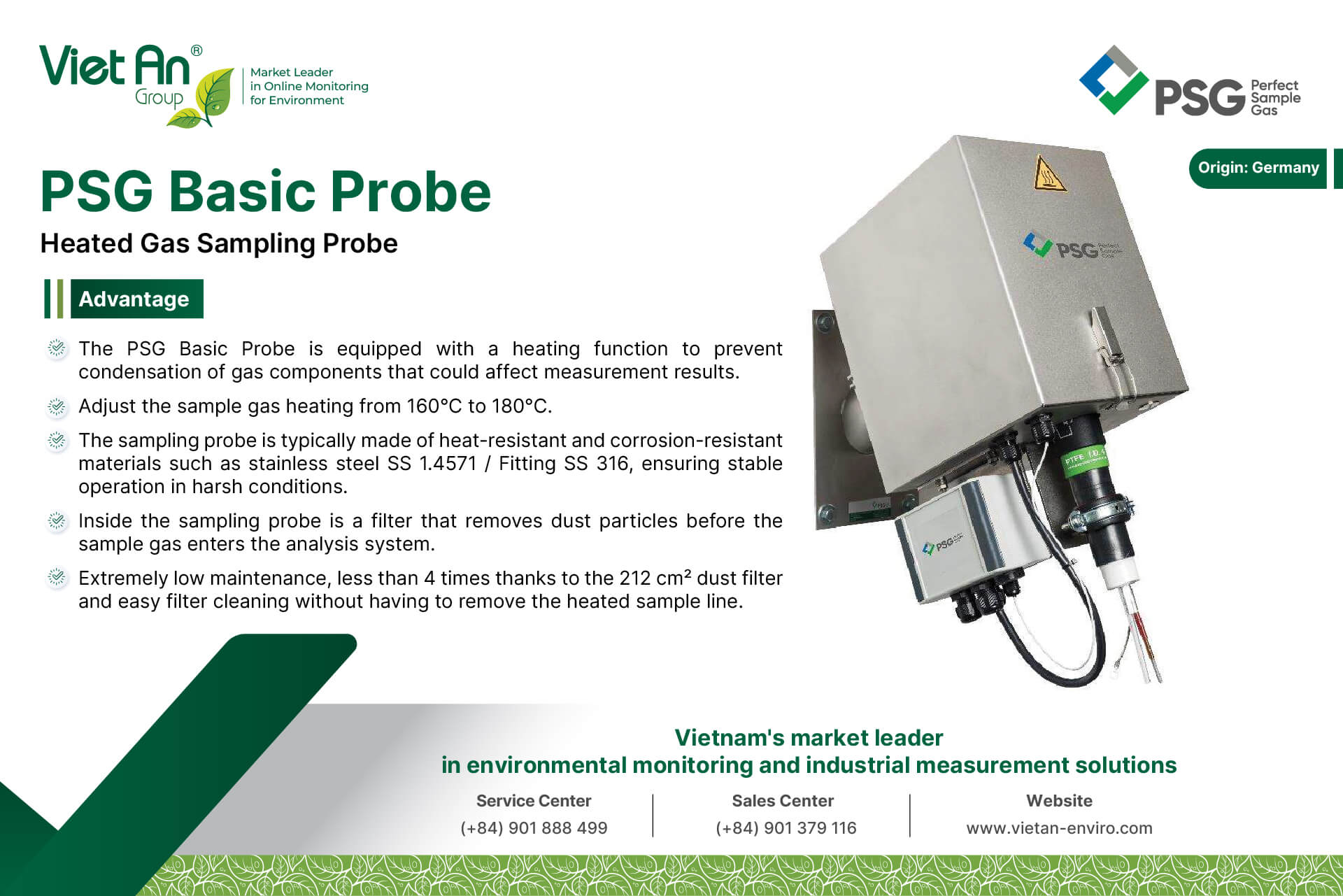

PSG Basic Probe - Heated Gas Sampling Probe

The PSG Basic Probe heated gas sampling probe is designed to address this issue. It continuously and stably samples and maintains the gas sample at a temperature of 160°C to 180°C. By heating and maintaining the temperature of the gas sample, it prevents the condensation of flue gas components, ensuring the accuracy of the flue gas analysis results.

The main components inside the PSG Basic Probe

Sampling head: PSG Basic Probe Samplers designed for demanding applications are constructed from heat-resistant and corrosion-resistant materials like stainless steel or special alloys. This allows for reliable operation in industrial environments with high temperatures and corrosive gases.

Dust filterThe device has a dust filter with a surface area of up to 212 cm², the largest on the market today. This filter removes dust and impurities from the exhaust gas before it enters the analyzer. The device can handle large exhaust gas volumes without clogging thanks to its large filter surface area.

Exhaust gas heater:: PSG Basic Probe Utilizing a high-efficiency closed-loop heating system, the device incorporates a thick layer of fiberglass insulation to maintain a uniform temperature, preventing heat loss during sampling. This eliminates condensation of water vapor, acids in the exhaust gas, or salt formation when the gas sample contains low levels of acidic/alkaline components such as NH3, ensuring accurate gas composition analysis.

Advantages of PSG Basic Probe

- Extremely low maintenance thanks to its 212 cm² dust filter surface.

- Maintenance is reduced by up to 75% compared to other filters at 100 mg/m³ dust loading.

- The sample gas can be heated to 250 °C or automatically regulated between 160 °C and 180 °C.

- Easy gas filter replacement without the need for tools or sample line disassembly.

- Corrosion-resistant construction with SS 1.4571 and SS 316 fittings.

- Calibration and backflush ports.

- Temperature alarm.

- The robust and compact design is suitable for outdoor use in demanding conditions.

- Handles low to medium dust loads and can be equipped with accessories for high dust loading applications.

PSG Basic Extruded - Heated gas sampling line

PSG Basic Extruded is a specially designed heated gas sampling tube for transporting flue gas from the exhaust stack to the analyzer station without altering the chemical composition of the gas.

PSG Basic Extruded is made of high-quality materials such as TPU (thermoplastic polyurethane), PE (polyethylene), or PVC (polyvinyl chloride). These materials are durable and resistant to harsh weather conditions, fire, and high temperatures.

The inner tube can be optionally upgraded with 1 to 12 sub-tubes made of materials such as PTFE (polytetrafluoroethylene), PFA (perfluoroalkoxy alkane), stainless steel, or special alloys, providing flexibility for various gas types.

Heating and insulation

The parallel heating cable system ensures a stable temperature along the entire length of the sampling line, preventing condensation of water vapor or acidic components in the gas sample. This is particularly important in low ambient temperature environments or when the gas sample contains condensable components.

The outer insulation, made of fiberglass or fleece, minimizes heat loss to the environment, maintaining a stable sample temperature and protecting operators from the hot surface.

Adjust the temperature

PSG Basic Extruded can be heated up to 200°C using an external temperature controller and an integrated PT100 temperature sensor, ensuring that the gas composition remains unchanged during transport to the analyzer, especially when maintaining a temperature above the dew point.

With an external temperature controller and a built-in PT100 sensor, the PSG Basic Extruded can be heated up to 200°C, preventing condensation and ensuring the integrity of the gas sample.

Advantages of PSG Basic Extruded

- Temperature can be easily adjusted using an external controller.

- The parallel heating cable configuration provides consistent temperature throughout the sample line.

- Maximum sample gas temperature can reach 200°C.

- The outer layer is constructed from flame-resistant and weatherproof materials such as PVC, PE, or TPU.

- Inner tubes are made of PTFE, PFA, stainless steel, or special alloys.

- Upgrade options include 1 to 12 inner tubes for simultaneously transporting multiple gases.

Special Cases

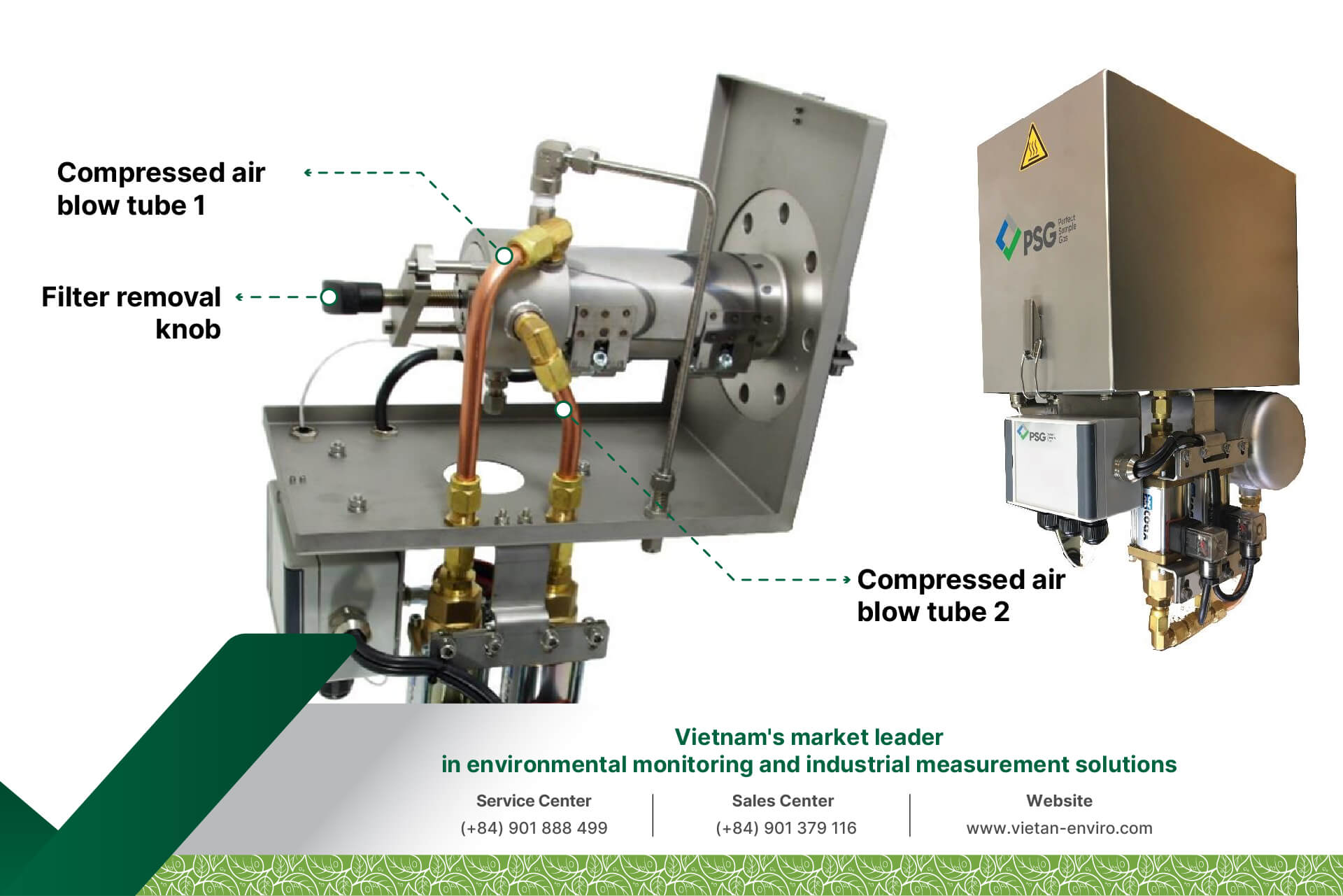

- High Dust Concentration Exhaust Gases

The dust filter surface can become clogged in applications where exhaust gases have very high dust concentrations. A clogged filter will lead to inaccurate sampling and may damage the equipment.

The PSG Plus Probe Double Back Purge is an upgraded version with a pneumatic filter cleaning system to address this issue. Its unique feature is a dual-stage back purge system that uses compressed air to blow back the accumulated dust without removing the filter for cleaning.

Even if manually cleaning the filter surface is required, removing the filter is very simple. It can be easily removed by simply grasping and twisting.

2. Exhaust Gas Temperature Below 90°C

For exhaust gases with an inlet temperature lower than 90°C, the heated sampling probe may not have enough time to heat the gas sample up to 180°C. This can cause condensation and alteration of the gas components, leading to inaccurate analysis results.

In this case, an additional device, the PSG HT 250 heated sampling tube, can preheat the exhaust gas before it enters the PSG Basic Probe. This ensures the gas sample reaches the required temperature and maintains its composition.

Introducing PSG (Perfect Sample Gas)

PSG (Perfect Sample Gas) specializes in providing gas sampling probes, heated sampling lines, and gas sample coolers for accurate gas sampling in various applications.

With over 45 years of experience, PSG, headquartered in Steinbach, Germany, offers more than 2500 versions of heated lines to ensure unaltered gas transport.

Imagine managing and analyzing your exhaust gas more quickly and efficiently than ever! No more worrying about complex maintenance or condensation damaging your gas sample and analyzer. The PSG Basic Probe and PSG Basic Extruded optimize your sampling and transportation processes, ensuring accurate and reliable measurement results. With a temperature resistance of up to 200°C and high customization capabilities, these two devices are perfect for all emission monitoring applications, from low to high.

Don't let exhaust gas monitoring challenges hinder your operations. Upgrade your system today with PSG Basic Probe and PSG Basic Extruded - the perfect solution for all industrial emission monitoring applications. Contact Viet An for detailed advice and to optimize your investment!

Việt An – Thị phần số 1 Việt Nam về Giải Pháp Quan Trắc Môi Trường và Đo Lường Công Nghiệp

🔘 Head Office (Ho Chi Minh City)

No.4E, Street 6, An Phu Ward, Thu Duc City, Ho Chi Minh City

(Sales) +84 902 970 009 | (Service) +84 901 888 499

🔘 Northern Viet An

Lô 33, khu BT4-1, khu nhà ở Trung Văn, phường Trung Văn, quận Nam Từ Liêm, Hà Nội

(Sales) +84 901 851 116 | (Service) +84 901 888 499

🔘 Central Viet An

No.5A Mai Xuan Thuong Str., Hoa Khe Ward., Thanh Khe Dist., Da Nang City

(Sales) +84 898 119 116 | (Service) +84 901 888 499

🔘 Việt An VP-Hà Tĩnh

03 Mai Thúc Loan, phường Kỳ Liên, Thị xã Kỳ Anh, Hà Tĩnh

(Sales & Service) +84 938 442 414